Language:

Understanding the Impact of Slurry Mixtures on Carbon Steel and Stainless Steel Investment Castings

Investment casting, a craft of precision and finesse, lies at the heart of manufacturing critical components for a wide spectrum of industries – from aerospace to automotive. Yet, amidst the intricate dance of molten metal and moulds, a subtle but vital element often goes unnoticed: the slurry mixture. In this exploration, we step into the world of investment casting to unravel the nuances that set apart the slurry mixtures tailored for two steel titans – carbon steel and stainless steel.

Together, we’ll uncover the profound repercussions of a mismatched blend, delving into the intriguing chemical reactions that can transform sturdy castings into flawed works of art. This journey through the realms of metallurgy and precision casting unveils the crucial significance of this seemingly unassuming facet of the process. Join us as we embark on this voyage, where precision harmonises with chemistry in the captivating artistry of investment casting.

Contents

The Role of Slurry Mixtures

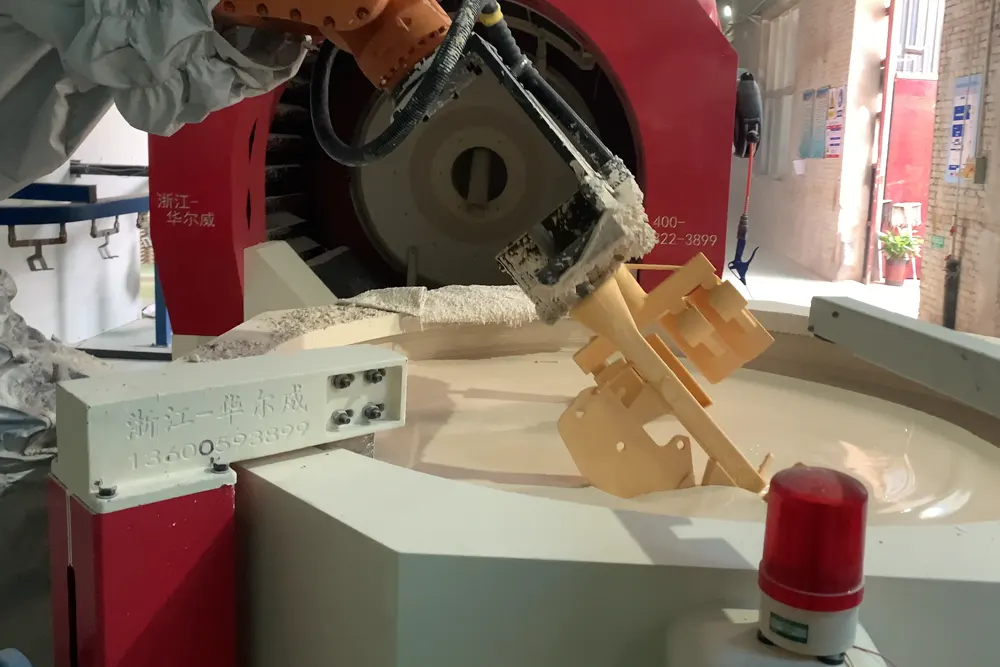

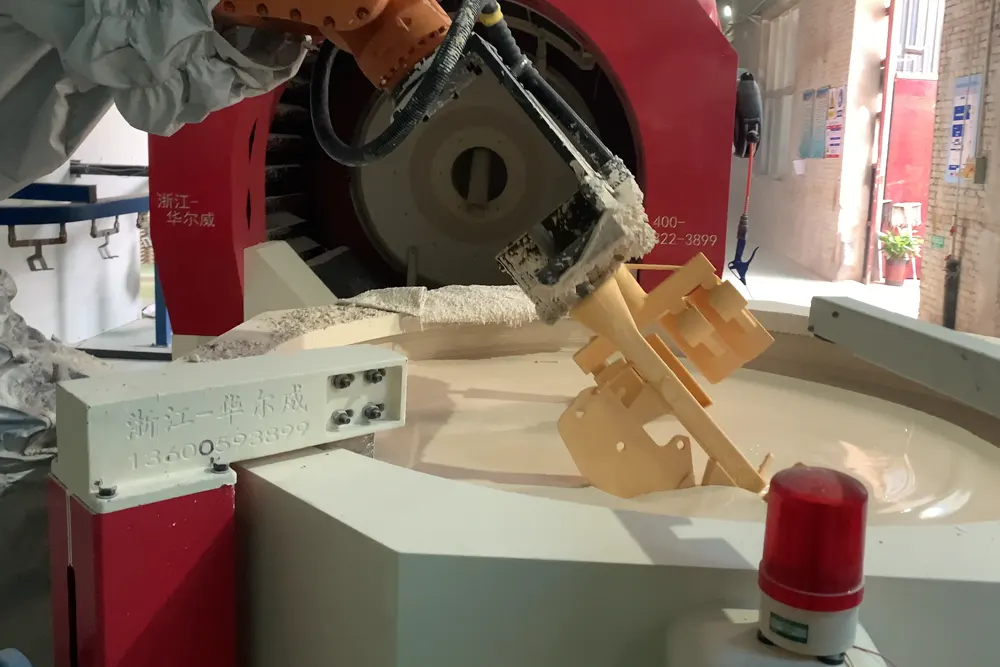

In the intricate world of investment casting, slurry mixtures assume a role of paramount importance. These meticulously crafted blends, composed of fine refractory materials suspended within a liquid binder, serve as the building blocks for the ceramic shells that envelope wax or plastic patterns. But what exactly is their purpose, and why is precision in their formulation crucial?

The Purpose of Slurry Mixtures

Slurry mixtures act as the initial canvas upon which the intricate art of investment casting is painted. Their primary function is to create a robust and heat-resistant ceramic shell around the wax or plastic patterns. This shell must be capable of withstanding the intense temperatures and stresses of the casting process.

Tailoring to Alloy Requirements

Yet, it is not a one-size-fits-all scenario. Different alloys, such as carbon steel and stainless steel, possess distinct properties, each demanding a bespoke approach. The importance of tailoring slurry mixtures to match specific alloy requirements cannot be overstated. Whether it’s the selection of refractory materials, the composition of the binder, or the meticulous control of viscosity, every aspect of the slurry must align with the needs of the alloy being cast.

Precision in this realm ensures that the resulting ceramic shell possesses the requisite thermal properties, dimensional stability, and surface finish to bring forth a casting of unparalleled quality. It is in this harmonious marriage of art and science, where slurry mixtures transform into the foundation upon which the success of investment casting rests.

Join us in the next section as we journey deeper into the world of slurry mixtures, exploring the subtleties that distinguish those crafted for carbon steel and stainless steel, and uncovering the consequences when precision falters.

Carbon Steel vs. Stainless Steel

In investment casting, the choice between carbon steel and stainless steel can make a huge difference. These differences extend beyond mere metallurgy; they influence not only the performance of the final casting but also the specific requirements of slurry mixtures.

Exploring the Key Differences

- Alloy Composition:

- Carbon Steel: At its core, carbon steel embodies a straightforward composition with iron and carbon as its primary elements. The carbon content, which can range from a fraction of a percent to a few percent, largely determines its properties.

- Stainless Steel: In contrast, stainless steel is an alloy enriched with chromium (usually at least 10.5%) and often other elements like nickel and molybdenum. These alloying elements impart corrosion resistance and a wide spectrum of mechanical properties.

- Mechanical Properties:

- Carbon Steel: Carbon steel, depending on its carbon content, can exhibit varying levels of hardness, strength, and ductility. High-carbon grades tend to be harder but less ductile.

- Stainless Steel: Stainless steel is renowned for its versatility. It can be engineered to offer a balance of strength, toughness, and ductility, making it suitable for diverse applications.

- Corrosion Resistance:

- Carbon Steel: Carbon steel is susceptible to corrosion when exposed to moisture and aggressive environments. Its corrosion resistance can be improved through protective coatings.

- Stainless Steel: Stainless steel’s hallmark feature is its resistance to corrosion. The chromium content forms a protective oxide layer on the surface, shielding it from rust and corrosion, even in harsh conditions.

Influence on Slurry Mixtures

These distinctions in alloy composition, mechanical properties, and corrosion resistance significantly influence the choice of slurry mixture. Slurry mixtures tailored for carbon steel must consider the potential for increased hardness and abrasiveness, which can impact the casting process. In contrast, slurry mixtures for stainless steel need to preserve the alloy’s corrosion resistance while accommodating its diverse mechanical requirements.

The art of investment casting extends beyond metallurgy; it’s a harmonious blend of science and craftsmanship. In the next section, we delve into the composition and characteristics of slurry mixtures for both carbon steel and stainless steel, uncovering the subtleties that ensure the success of precision casting.

Slurry Mixtures for Carbon Steel

When it comes to crafting precision castings in carbon steel, the magic begins with the careful formulation of slurry mixtures. These bespoke concoctions play a pivotal role in creating ceramic shells that can withstand the unique demands of carbon steel.

Composition and Characteristics

Slurry mixtures tailored for carbon steel are crafted with a specific set of characteristics in mind. They typically consist of fine refractory materials suspended within a liquid binder. The composition often includes elements like zircon, alumina, or silica, chosen for their ability to withstand the elevated temperatures encountered during the casting of carbon steel.

The liquid binder, a crucial component, is formulated to provide optimal adhesion to the wax or plastic patterns. It must also support the creation of a stable and robust ceramic shell that can endure the stresses of carbon steel casting.

Requirements for Quality Carbon Steel Castings

Achieving a high-quality carbon steel casting hinges on precise adherence to the requirements set by these slurry mixtures:

- Thermal Properties: The ceramic shell must exhibit excellent thermal properties, capable of withstanding the extreme temperatures encountered during the casting process. The slurry mixture’s composition and refractory materials must align with this requirement.

- Dimensional Stability: Maintaining the integrity of the ceramic shell’s dimensions is critical. Any deviations can lead to casting defects. Proper control of viscosity and adherence to slurry mixture specifications ensure dimensional stability.

- Surface Finish: Carbon steel castings often require a smooth surface finish. The slurry mixture must be designed to create a shell that can capture fine details and result in a pristine surface on the final casting.

- Heat Resistance: Carbon steel’s high melting point necessitates a ceramic shell that can endure these elevated temperatures without cracking or deforming. The slurry’s formulation and drying process must ensure heat resistance.

Slurry Mixtures for Stainless Steel

Crafting stainless steel castings demands a unique blend of artistry and chemistry. The composition of slurry mixtures tailored for stainless steel is a precise science, ensuring the preservation of the alloy’s corrosion resistance while accommodating its diverse mechanical requirements.

Composition and Attributes

Slurry mixtures designed for stainless steel castings comprise a carefully balanced combination of components. They typically consist of fine refractory materials suspended within a liquid binder, but with a distinct focus on preserving the alloy’s corrosion-resistant properties.

The binder plays a critical role in these mixtures. It must not only provide excellent adhesion to the wax or plastic patterns but also be compatible with the specific requirements of stainless steel alloys. The refractory materials selected should match the solidification characteristics and thermal expansion properties of stainless steel.

Critical Factors in Maintaining Corrosion Resistance

Preserving stainless steel’s corrosion resistance during the investment casting process requires meticulous attention to several critical factors:

- Binder Compatibility: The binder’s formulation must be chosen with care to ensure that it does not introduce contaminants or reactions that compromise the alloy’s corrosion resistance.

- Refractory Materials: The selection of refractory materials within the slurry mixture should align with the corrosion-resistant properties of stainless steel. It’s crucial to avoid elements that could potentially degrade the protective oxide layer on the stainless steel surface.

- Drying and Firing: The drying and firing process of the ceramic shell must be closely monitored and controlled to prevent any adverse effects on the alloy’s corrosion resistance. Proper heating and cooling profiles are essential.

- Quality Control: Rigorous quality control measures should be in place to monitor the composition, thickness, and uniformity of the ceramic shell, ensuring that it adheres to the strict requirements of stainless steel casting.

In the intricate dance of metallurgy and precision casting, slurry mixtures tailored for stainless steel act as the guardians of corrosion resistance.

The Consequences of Using the Wrong Mixture

In the precision world of investment casting, the use of an incorrect slurry mixture for stainless steel casting can trigger a cascade of chemical reactions, profoundly affecting material properties and overall performance. Let’s delve into the intricacies of these reactions and their far-reaching consequences.

Detailing Chemical Reactions

When an unsuitable slurry mixture is introduced to the stainless steel casting process, a critical transformation takes place. Carbon, typically present in the incorrect mixture, interacts with the alloy’s chromium content, setting in motion the formation of chromium carbides.

Formation of Chromium Carbides

Chromium carbides, such as Cr23C6 and Cr7C3, emerge as stable compounds in this chemical reaction. These carbides precipitate within the stainless steel matrix, drawing chromium away from the alloy. The consequences of this phenomenon are serious:

- Reduced Corrosion Resistance: As chromium is depleted from the stainless steel matrix to form chromium carbides, the material’s ability to form a protective chromium oxide layer on the surface is compromised. This depletion leaves the stainless steel vulnerable to corrosion, particularly in chloride-rich environments.

- Intergranular Corrosion: The regions surrounding the chromium carbides become susceptible to intergranular corrosion. This type of corrosion targets grain boundaries, further diminishing the alloy’s integrity.

- Decreased Toughness: The presence of chromium carbides can lead to reduced material toughness and impact resistance. Stainless steel, known for its balanced combination of strength and ductility, may lose these vital attributes.

Chemical Reactions at the Interface

When the incorrect slurry mixture for stainless steel is used to create the ceramic shell, it may not possess the necessary chemical stability to withstand the high temperatures and reactive nature of molten iron. This mismatch can lead to several chemical reactions at the interface between the ceramic shell and the poured iron:

- Oxidation of Shell Components: The high temperatures of molten iron can cause the oxidation of components within the ceramic shell. This includes the refractory materials and binders present in the shell mixture. As they oxidise, they may release gases and compounds, potentially compromising the shell’s integrity.

- Formation of Silicates: In the presence of oxygen from the air and high temperatures, elements like silicon in the ceramic shell mixture can react with oxygen to form silicate compounds. These silicates can weaken the shell, making it more susceptible to cracking or thermal shock.

- Release of Volatile Compounds: Some components in the incorrect slurry mixture may release volatile compounds when exposed to high temperatures. These compounds can further compromise the shell’s structural integrity or create voids.

- Contamination of Molten Iron: The chemical reactions at the ceramic shell’s interface can lead to the release of contaminants into the molten iron. These contaminants can have detrimental effects on the properties of the iron, potentially leading to casting defects.

Impact on pH Stability:

- Change in pH Levels: The use of an incorrect slurry mixture, particularly one with components not suitable for stainless steel casting, can alter the pH levels within the ceramic shell and the surrounding environment. This alteration is primarily due to the chemical reactions that occur when the incorrect mixture interacts with the high temperatures and chemical composition of molten iron.

- Release of Alkaline or Acidic Compounds: Depending on the specific composition of the incorrect slurry mixture, it may release alkaline or acidic compounds when exposed to the high temperatures of the molten metal. For instance, some components may oxidize and release acidic gases, while others may introduce alkaline elements into the system.

- pH Fluctuations: These released compounds can cause fluctuations in the pH levels of the casting environment. This change in pH can have several detrimental effects, including:

- Chemical Reactions: pH fluctuations can trigger additional chemical reactions within the ceramic shell and the molten metal. These reactions can impact the integrity of both the shell and the casting.

- Shell Erosion: An unstable pH environment can lead to the erosion or breakdown of the ceramic shell, compromising its ability to protect the casting.

- Contaminants: pH changes may also affect the composition of the molten metal, potentially introducing contaminants that affect its metallurgical properties and overall quality.

- Casting Defects: Fluctuations in pH can result in casting defects, such as surface roughness, dimensional inaccuracies, or porosity.

Consequences for the Casting

The chemical reactions between the ceramic shell and molten iron can result in various consequences for the final casting:

- Shell Erosion: The shell may erode or break down prematurely, causing surface defects and compromising the casting’s integrity.

- Contamination: Contaminants released from the shell can introduce impurities into the molten iron, affecting its metallurgical properties and leading to casting defects.

- Reduced Quality: The overall quality of the casting may be compromised, with potential defects like surface roughness, dimensional inaccuracies, or porosity.

- Material Integrity: In severe cases, the chemical reactions can lead to structural weaknesses in the casting, making it more susceptible to failure.

To prevent such chemical interactions and their associated consequences, it is crucial to employ the correct slurry mixture tailored for stainless steel when creating the ceramic shell. Additionally, stringent quality control measures and precise process management are indispensable to ensure that the casting process upholds the integrity of both the shell and the poured metal. Taiyuan Simis Investment Casting Co., Ltd always assures strict quality control in the casting process. In contrast, some other Chinese manufacturers opt for slurry mixtures intended for carbon steel (since they are usually cheaper) in the crafting of stainless steel components, resulting in the failure of the entire production lot.

In conclusion, the selection of the right slurry mixture and the commitment to quality control are the cornerstones of successful stainless steel investment casting. At Taiyuan Simis Investment Casting Co., Ltd, we take pride in our dedication to excellence, ensuring that every stainless steel component we craft meets the highest standards of quality and reliability. We encourage industry stakeholders to prioritise precision and expertise in the investment casting process, safeguarding the integrity and performance of stainless steel castings for a wide range of critical applications.