Language:

INVESTMENT CASTING PROCESS

At the heart of precision manufacturing, investment casting stands out as an artful technique, delivering unmatched intricacy and precision. With a mastery of this exceptional method, we take pride in supplying high-quality products and offering investment casting service that meet your exacting standards. Our investment casting process has allowed us to offer you distinct advantages in precision manufacturing.

What Is Investment Casting?

Investment casting, also referred to as lost wax casting, represents a meticulous manufacturing process known as the investment casting process, designed for the creation of intricate and finely detailed metal components. This method commences with the formation of a wax pattern that replicates the desired part. The wax pattern is then enveloped in a ceramic shell, forming a mould of the component. Subsequently, the wax is melted away from the mould, leaving behind a void that mirrors the intended metal part.

The next step involves pouring molten metal into this ceramic mould cavity. Once the metal cools and solidifies, the ceramic shell is carefully removed, unveiling the finished metal component with exceptional precision and dimensional accuracy.

Investment casting is highly regarded for its ability to produce complex parts with intricate details. It is a preferred method in aerospace, automotive, medical, agriculture, machinery, engineering, and various other industries where exactness and quality are paramount. This versatile casting technique offers remarkable design flexibility and is well-suited for crafting small to medium-sized components with intricate features. Whether you need a single prototype or a large-scale production run, our investment casting service can meet your specific needs with precision and expertise.

Investment Casting Process

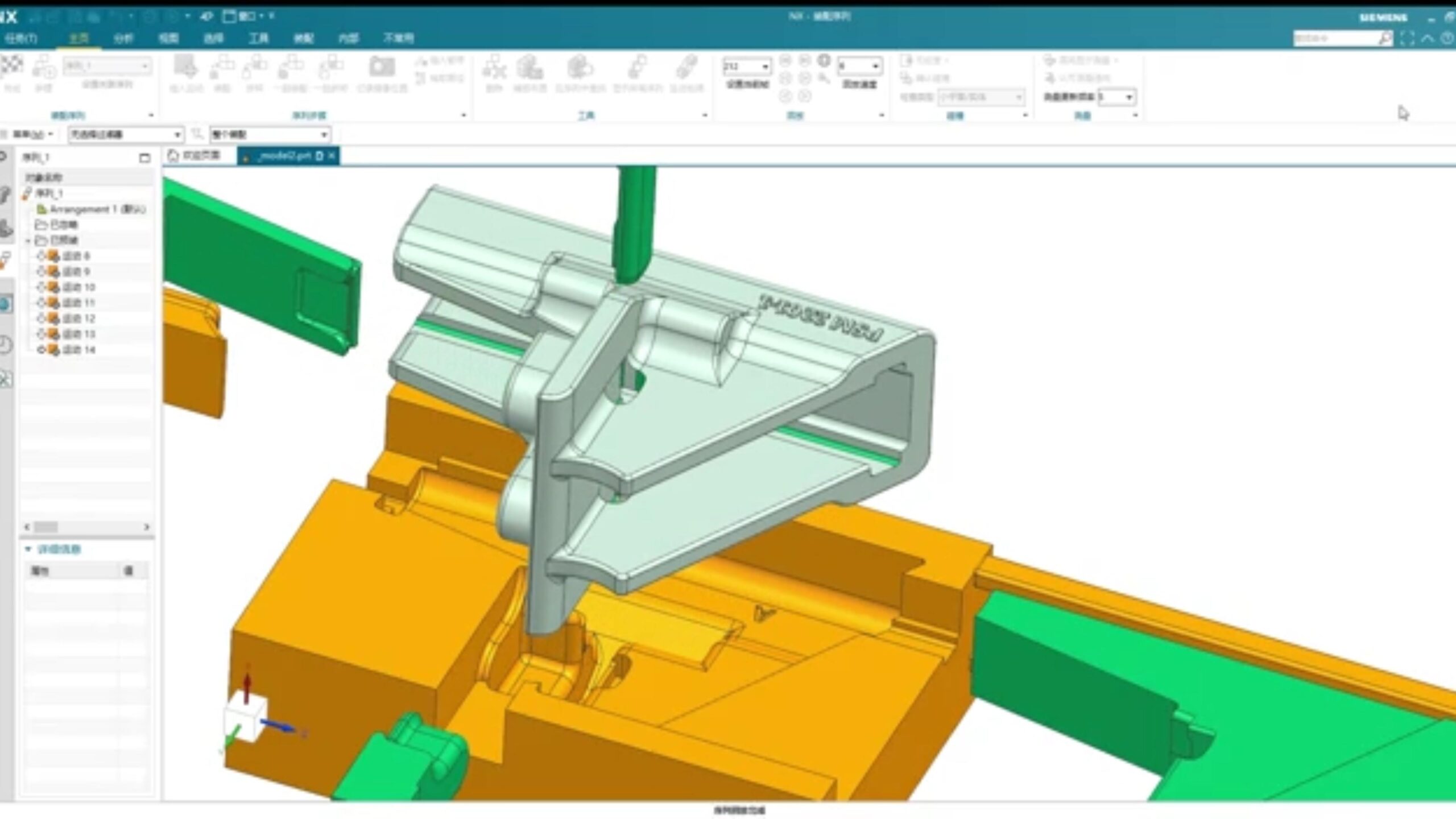

1. Tooling design and manufacturing.

Tooling design in investment casting is the process of crafting wax or plastic patterns that precisely mirror the shape, dimensions, and intricate features of the desired metal component. These patterns serve as the moulds for the molten metal during the investment casting process. Tooling designers employ computer-aided design (CAD) software to create highly accurate digital models, accounting for factors such as shrinkage compensation, gating system design, and venting.

The parting line, where the mould will be separated into two halves, is thoughtfully chosen to minimise visible seams on the final casting. Core design, if needed for internal features, is seamlessly integrated into the pattern. Material selection for the pattern is critical, with consideration for dimensional stability and compatibility with the investment casting process.

Attachment points on the pattern ensure secure assembly, while ease of pattern removal from the ceramic shell is carefully planned. Pattern design is a pivotal step, ensuring that the investment casting process yields accurate, high-quality components.

With over 40 years of experience of providing investment casting service, Taiyuan SIMIS Co. Ltd specialises in the independent design and in-house manufacturing of tools tailored for investment casting. Our expertise extends to a diverse range of mould types, including automatic wax injection moulds, manual wax injection moulds, and automatic opening moulds, all designed to accommodate various casting structures. We take pride in our ability to provide custom tooling design, tailored to fit different wax machines and specific casting requirements, ensuring precision and quality throughout the investment casting process.

2. Wax Mould Production

To accommodate various structures and quantities of investment castings, we possess multiple types of wax injection machines, including fully automatic, semi-automatic, and manual models. Additionally, we have a fully automated system for mould material preparation and recovery. Following the creation of the wax moulds, we carefully inspect its dimensions and surface quality, making necessary repairs as needed. Subsequently, depending on the casting structure, the wax mould is affixed to the gate or riser wax rod to prevent any shrinkage holes in the casting. The assembled wax tree, formed by welding, is conveyed through an automated line to undergo the shell-making process.

3. Shell Making Process

The primary and crucial stage in investment casting process lies within the shell-making process. The creation of the ceramic shell in investment casting begins with the fabrication of wax or plastic patterns that faithfully replicate the final metal components.

These patterns are affixed to a central sprue, forming a cluster known as the “tree,” which facilitates the flow of molten metal into the cavity shaped by the patterns. Subsequently, the wax tree is immersed in a slurry mixture containing finely-ground ceramic particles suspended within a liquid binder.

This initial coating firmly adheres the ceramic particles to the wax surface, establishing the foundation for successive layers. After immersion, the tree is permitted to dry, allowing the ceramic coating to harden. This process is then repeated multiple times, with alternating layers of ceramic slurry and stucco (a coarser refractory material) meticulously applied to the tree.

Each layer undergoes thorough drying before the addition of the next, continuing until a robust and uniform ceramic shell is intricately crafted. The meticulous control of ceramic slurry composition, coating thickness, and drying intervals is essential to ensure the formation of a durable and flawless shell, a critical aspect of the investment casting process.

4. Mould Dewaxing

The silica sol shell process, a part of the investment casting process, exclusively employs the steam dewaxing technique. We employ a sizeable 3m³ dewaxing machine operating at 0.7MPa pressure, ensuring the efficient removal of wax within a 30-minute timeframe. Following dewaxing, the interior of our high-strength shell showcases a lustrous, ceramic-like finish. The surface roughness and dimensional precision of the castings we produce exceed those achieved through the use of water glass binders by two grades.

5. Shell Firing

Shell Firing is a crucial step in our investment casting process, and at the heart of this operation lies our indispensable calcining shell kiln. To accommodate the high-strength characteristics of our shells, we rely on a tunnel kiln spanning an impressive 30 meters in length, meticulously heated using pollution-free natural gas. The shells undergo a gradual heating process, commencing at a low-temperature 200°C calcination and gradually reaching a high-temperature 950°C calcination.

This deliberate approach safeguards against deformation or cracking induced by sudden temperature changes. Ultimately, the calcining process in our state-of-the-art kiln ensures the shells attain the requisite strength and precision vital for our investment casting process.

6. The smelting and pouring

The smelting and pouring is one of the most important phases in the entire investment casting process, representing one of the core strengths of our company. We possess the expertise to precisely smelt various materials, ensuring that the chemical composition requirements of the investment castings are met.

In addition to carbon steel, we excel in handling specialised steel types, including high-alloy steel, stainless steel, heat-resistant steel, wear-resistant steel, high manganese steel, and other distinctive steel alloys.

Our commitment to quality extends to the stability of molten steel’s chemical composition, free from impurities or internal defects such as pores. Before tapping the molten steel, we subject it to three spectral inspections to verify its composition and perform temperature checks twice using a thermocouple. We employ the finest deoxidisers and slag-making agents available in China to guarantee the quality of each casting.

During pouring, we utilise Teapot ladles, effectively preventing impurities from entering the castings. Furthermore, we conduct secondary deoxidation in the ladle to further enhance the internal quality of the castings.

7. Cooling, Solidification, and De-Shelling

After the precise pouring of molten metal into ceramic shell moulds, a crucial step in the investment casting process, castings undergo cooling, solidification, and de-shelling. De-shelling involves meticulously removing the ceramic shell material. Simis enhances this stage with advanced hanging-type fully automatic equipment, ensuring efficient and precise shell removal and dust removal.

Once de-shelling is complete, the castings emerge, revealing their intricate shapes. They then move on to finishing, quality control, and inspection stages, ensuring they meet rigorous standards. The ‘Cooling, Solidification, and De-Shelling’ stage is pivotal, shaping castings into their final form before further refinement and quality checks.

8. Finishing and Inspection

This is the last stage in the investment casting process, it is vital for ensuring that our investment castings meet stringent quality standards and specifications, providing our customers with products of exceptional quality and precision.

At Simis, we take quality assurance seriously. Our commitment to delivering top-notch castings is underpinned by our ISO9000 quality management system and TS16949 certification, which provide robust support for our quality assurance system.

We’ve established a fully-equipped casting mechanical properties and chemical composition analysis testing center. This Top-of-the-line facility allows us to comprehensively analyze and test the chemical composition and mechanical performance of different materials. Our key equipment includes:

- Spectrometer

- Mechanical performance tensile testing machine

- Impact equipment capable of performing room temperature and low-temperature (-45°C) impact tests, complete with machined impact test piece notch equipment

- Metallographic inspection equipment

- Rockwell hardness tester

- X-ray detection equipment

- Ultrasonic detector

- Magnetic particle flaw detection equipment

- Penetrant testing

The results of these rigorous tests and analyses, along with corresponding samples, are meticulously archived and organized by date and customer. We also provide detailed inspection reports to our valued clients, ensuring transparency and quality assurance throughout the entire investment casting process.

Investment Casting Advantages

At Taiyuan SIMIS Investment Casting Co. Ltd., we take pride in elevating the inherent advantages of the investment casting process to deliver unparalleled quality and precision. As a leading China investment casting foundry with over four decades of experience, we offer precision investment casting services to cater to diverse industries, making us a trusted name in the foundry industry.

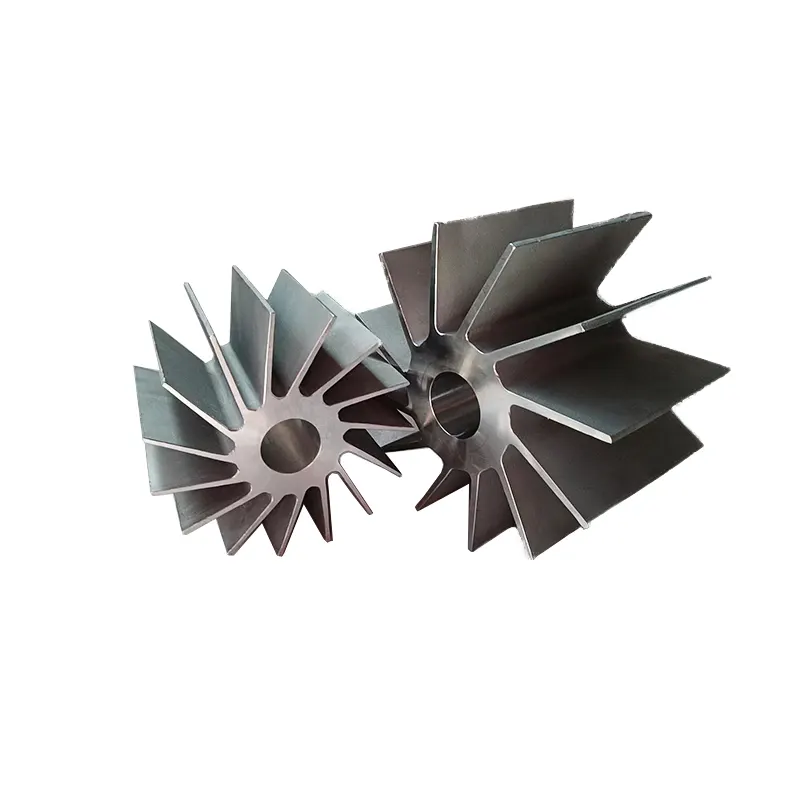

Precision and Intricacy

Investment casting process excels in producing intricate and finely detailed components. Taiyuan SIMIS leverages this advantage by employing skilled and experienced engineers who ensure that every casting meets the highest industry standards.

Design Flexibility

Our commitment to precision extends to design flexibility. Taiyuan SIMIS uses advanced technologies to bring even the most complex geometries and shapes to life, providing tailored solutions that meet your specific requirements.

Versatility

As a seasoned investment casting foundry, Taiyuan SIMIS offers a wide range of materials, including high-strength steel, stainless steel, high-nickel steel, high-manganese steel, and more. This versatility ensures that our investment casting service is suitable for diverse applications across industries.

Cost-Effectiveness

Taiyuan SIMIS understands the importance of cost-effectiveness. By minimising machining and material waste, we offer cost-effective solutions for small to medium-sized production runs, enhancing your bottom line.

Quality and Surface Finish

Our dedication to quality is reflected in the superior surface finish and quality of every component we produce. Taiyuan SIMIS invests in state-of-the-art equipment and stringent quality control measures to consistently deliver parts that surpass expectations.

Reduced Post-Processing

With our robust production capabilities, we minimise the need for extensive post-processing, ensuring that you receive finished components efficiently.

Wide Industry Applications

Our investment casting service serves a diverse customer base across various industries, including aerospace, automotive, locomotive, medical, machinery, agriculture, and more. Our investment casting service cater to your industry’s specific needs.

Environmental Considerations

We are committed to environmentally friendly practices. Taiyuan SIMIS investment casting co., ltd minimises material wastage during the investment casting process, aligning with eco-conscious manufacturing principles.

Incorporating SIMIS’ expertise and our China foundry status, we enhance the inherent advantages of investment casting to provide tailored solutions for your precision component needs. Explore how our commitment to precision, innovation, and customer satisfaction elevates the benefits of investment casting across industries.

Credentials Beyond Compare

We are a professional investment casting foundry with a long-standing ISO 9001 certification, which reflects our ongoing dedication to maintaining high-quality management practices and our consistent delivery of top-notch products and services while meeting customer regulatory requirements. Additionally, we have received certification from TUV, affirming our commitment to upholding stringent quality standards and our continued pursuit of excellence.

Request a Quote

Trending now