Language:

The Major Differences Between China and the UK Investment Casting Manufacturers

When comparing investment casting manufacturers in China and the United Kingdom we are looking at several factors, including their manufacturing capabilities, market focus, cost structures, regulatory environments, and technological advancements. Here’s an overview of the potential differences:

Table of Contents

Cost and pricing

Cost and pricing are critical factors in the manufacturing industry, especially in investment casting, and they can significantly vary between manufacturers in China and the United Kingdom. Here’s a more detailed look at these aspects:

China

Lower Labour Costs: One of the primary reasons for the lower cost of manufacturing in China is the comparatively lower labour costs. This allows Chinese manufacturers to offer more competitive prices.

Economies of Scale: Chinese manufacturers often operate on a larger scale, which drives down the cost per unit. This is particularly advantageous for large-volume orders.

Supply Chain Advantages: China’s well-established supply chains for raw materials and components can reduce costs. Their extensive manufacturing infrastructure also contributes to cost efficiency.

Overhead Costs: Overhead costs, including facility maintenance, utilities, and administrative expenses, are generally lower in China, contributing to more competitive pricing structures.

Market Competition: The high number of manufacturers in China creates a competitive market, often leading to more attractive pricing to win business.

United Kingdom

Higher Labour Costs: Labour costs in the UK are typically higher than in China, reflecting the higher cost of living and minimum wage standards. This contributes to higher overall manufacturing costs.

Regulatory Compliance Costs: The UK’s stringent regulatory standards, especially in industries like aerospace, automotive, and healthcare, can increase the cost of compliance, which is often passed on to the customer.

Smaller Scale Operations: UK manufacturers may operate on a smaller scale compared to their Chinese counterparts. While this can be advantageous for quality and customization, it often means higher per-unit costs.

Focus on Specialisation and Quality: UK manufacturers may focus more on specialised, high-quality, bespoke production, which typically demands a higher price due to the expertise and precision involved.

Economic Factors: Factors like currency exchange rates, taxation, and economic policies in the UK can also influence the cost structures of manufacturing.

Impact on Pricing Price Sensitivity: Customers with high price sensitivity, especially those requiring large volumes without highly specialised needs, may lean towards Chinese manufacturers for cost benefits. Value vs. Cost: Customers prioritising specific quality standards, specialised requirements, or regional manufacturing may find the higher cost of UK manufacturers justifiable for the value they provide. Total Cost of Ownership (TCO): It’s important to consider the TCO, which includes not just the initial price but also costs related to logistics, import duties, potential delays, and quality control. Sometimes, lower upfront costs can lead to higher long-term expenses.

Scalability

Scalability in the context of investment casting manufacturers in China and the United Kingdom can vary significantly, influenced by several factors including manufacturing capabilities, infrastructure, and market focus.

China

Large-Scale Production Capabilities: Chinese manufacturers are typically equipped to handle large-scale production runs efficiently. This is due to their extensive manufacturing facilities and abundant workforce.

Flexibility in Volume Adjustments: Given the size and scope of many Chinese manufacturing plants, they are often able to scale production up or down relatively quickly in response to market demands or customer needs.

Supply Chain Robustness: The comprehensive and mature supply chains in China support scalability, ensuring that raw materials and components are readily available to meet increased production requirements.

Investment in Infrastructure: Over the years, China has heavily invested in its manufacturing infrastructure, enhancing its capacity to produce large volumes while maintaining cost-effectiveness.

United Kingdom

Specialised Production: UK manufacturers often specialise in smaller-scale, bespoke, or high-precision production runs. This focus on customisation and quality may limit the scale at which they operate.

Adaptability to Market Niches: UK manufacturers tend to be more nimble and adaptable to niche markets, which may not require the same volume scalability as mass markets.

Capacity for Gradual Scaling: While UK manufacturers may not typically operate on the same scale as their Chinese counterparts, many are capable of scaling up operations, though this might involve more lead time and investment in resources.

Focus on Advanced Technologies: UK investment casting facilities often focus on incorporating advanced technologies and automation, which can aid in scalability, particularly for complex and precision products.

Impact on customer choice

Volume Requirements: Customers with large volume requirements may find Chinese manufacturers more suited to their needs due to their ability to produce high volumes at a lower cost. In contrast, UK manufacturers might be preferred for lower volumes or when high precision and customisation are critical.

Market Responsiveness: Chinese manufacturers can typically respond to bulk market demands more rapidly due to their larger scale of operations. UK manufacturers, while possibly less equipped for massive scale-ups, can offer more personalised service and adapt quickly to specialised market requirements.

Investment Considerations: For businesses considering long-term partnerships, it’s important to evaluate whether the manufacturer can scale operations in alignment with projected growth and market trends.

Quality standards and regulations

Discussing the quality standards and regulations in the investment casting industry, particularly in the context of China and the United Kingdom, is important as these factors significantly impact the manufacturing processes, product quality, and market compliance.

China

Evolving Quality Standards: Chinese manufacturers have made substantial strides in improving quality standards over the years. However, there can be variability in quality among different manufacturers. It’s crucial for customers to perform due diligence when selecting a Chinese manufacturer.

ISO Certifications: Many leading Chinese investment casting manufacturers hold ISO certifications (such as ISO 9001 for quality management systems) which indicate compliance with international standards.

Regulatory Environment: China’s regulatory framework for manufacturing has been evolving to meet global standards. This includes regulations not only on the quality of the products but also on aspects like environmental compliance and worker safety.

Global Market Compliance: As Chinese manufacturers often serve international markets, they are increasingly aligning their practices with global standards to ensure compliance, especially in industries like automotive, aerospace, and medical devices.

United Kingdom

Stringent Quality Control: The UK is known for its stringent quality control and high manufacturing standards. UK investment casting manufacturers typically adhere to rigorous testing and quality assurance protocols.

Comprehensive Regulatory Framework: The UK has a comprehensive regulatory framework, especially for industries that require high precision and reliability, such as aerospace, defence, and medical equipment. These regulations ensure that products meet the highest safety and quality standards.

Certifications and Standards Compliance: UK manufacturers often hold various certifications like ISO 9001, AS9100 (aerospace industry standard), and ISO 13485 (medical devices), reflecting their commitment to quality and industry-specific requirements.

Consistency in Quality: Due to the high regulatory standards and consistent quality control processes, UK manufacturers are generally perceived as providing consistently high-quality products.

Impact on customer decisions

Risk Management: Customers who require high-reliability parts, or who operate in highly regulated industries, may prefer manufacturers from the UK due to their adherence to strict quality and regulatory standards.

Quality Assurance: While many Chinese manufacturers deliver high-quality products, customers might have to undertake more extensive supplier audits and quality checks to ensure consistency, compared to working with UK manufacturers.

Market Access: Compliance with regional and international regulations is crucial for market access. UK manufacturers are well-versed in EU and other international regulations, which can be advantageous for customers targeting these markets.

Customisation and Precision: For projects requiring high levels of customisation or precision, UK manufacturers’ adherence to stringent quality controls can be particularly beneficial.

Technological Advancements

Both nations have unique strengths and approaches to incorporating technology in manufacturing processes.

China

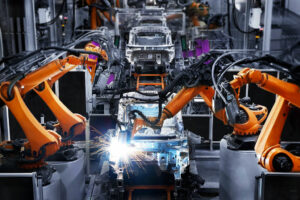

Rapid Technological Adoption: Chinese manufacturers are known for rapidly adopting new technologies to enhance efficiency and productivity. This includes automation, advanced software for design and simulation, and robotics in manufacturing.

Investment in Research and Development (R&D): China has significantly increased its investment in R&D, focusing on advancing manufacturing technologies. This includes developing new materials, refining casting methods, and exploring digital manufacturing solutions.

Scale and Modernisation: The scale at which Chinese manufacturers operate allows them to implement large-scale technological upgrades. Modernisation efforts in recent years have focused on not just increasing output but also improving quality and reducing environmental impact.

Global Technology Integration: Chinese manufacturers often integrate technologies and practices from around the world, blending local expertise with international advancements to enhance their manufacturing capabilities.

United Kingdom

Focus on Innovation and Specialisation: The UK has a strong tradition of innovation in engineering and manufacturing. UK investment casting manufacturers often focus on specialising in advanced, high-quality casting techniques, using cutting-edge technologies.

Collaboration with Academic and Research Institutions: UK manufacturers frequently collaborate with universities and research institutions. This collaboration drives advancements in materials science, precision engineering, and process optimisation.

Leadership in Niche Technologies: The UK excels in developing and utilising niche technologies, particularly for industries requiring high precision and customisation, such as aerospace, automotive, and medical devices.

Sustainability and Green Technologies: There is a growing focus in the UK on sustainable manufacturing processes. This includes the development and adoption of environmentally friendly technologies and practices in investment casting.

Conclusion: The Strengths and Advantages of Taiyuan Simis Investment Casting Co., Ltd.

- Cost-Effectiveness in Precision Casting: Taiyuan Simis, as a leading Chinese investment casting manufacturer, offers cost-effective solutions in precision casting. Their competitive pricing strategy, without sacrificing quality, is a crucial advantage for clients who seek value in their investment casting needs.

- Large-Scale Production in Investment Casting: Leveraging China’s expansive manufacturing infrastructure, Taiyuan Simis is adept at managing large-scale production runs efficiently. This capability is especially valuable in the field of investment casting, where they can meet high-volume orders while maintaining consistent quality.

- Versatility in Lost Wax Casting Materials: A hallmark of Chinese manufacturers like Taiyuan Simis is their ability to work with a diverse array of materials in lost wax casting. This versatility allows them to cater to a wide range of industry requirements, enhancing their appeal across various sectors.

- Responsive and Flexible Manufacturing: Taiyuan Simis likely exemplifies the flexibility and responsiveness characteristic of Chinese manufacturers. This adaptability is particularly beneficial in the dynamic field of investment casting, where client requirements can rapidly evolve.

- Global Reach in Investment Casting Services: Situated in a major global manufacturing hub, Taiyuan Simis likely enjoys a strong international presence. This global reach is crucial in understanding and fulfilling the diverse needs of the investment casting market.

- Technological Advancements in Precision Casting: In line with China’s rapid adoption of new technologies, Taiyuan Simis likely utilises modern techniques and equipment in precision casting. Such technological prowess contributes to enhanced efficiency and superior product quality.

- Commitment to Quality in Investment Casting: Despite the perception of variable quality in Chinese manufacturing, companies like Taiyuan Simis are committed to high standards in investment casting. They likely adhere to strict quality control processes and hold relevant certifications, ensuring reliable product quality.

- Robust Supply Chain for Lost Wax Casting Materials: Taiyuan Simis benefits from China’s extensive and mature supply chains, crucial for a consistent supply of materials needed in lost wax casting. This robust supply chain supports steady production schedules and helps in meeting deadlines.

Strategic Advantages

- Balancing Price and Quality in Investment Casting: Taiyuan Simis’s ability to balance cost-effective pricing with high-quality standards in investment casting makes them a preferred choice for many clients.

- Customisation and Material Expertise in Lost Wax Casting: Their expertise in handling various materials and customising solutions positions Taiyuan Simis as a versatile and adaptable manufacturer in the lost wax casting industry.

- Understanding Global Market Dynamics in Precision Casting: Their position in the global market equips Taiyuan Simis with insights into diverse market trends, beneficial for providing globally relevant and appealing precision casting solutions.

In summary, Taiyuan Simis Investment Casting Co., Ltd. embodies the strengths and competitive advantages of an adept Chinese manufacturer in the investment casting industry. Their expertise in lost wax casting, commitment to quality in precision casting, and capability to handle large-scale production are key attributes that position them favourably in the global market, offering significant benefits to a wide-ranging international clientele.