Language:

Revolutionising the Automotive Industry: Investment Casting Applications

In modern day manufacturing, the automotive industry stands as a crucible of innovation and precision. The quest for improved performance, fuel efficiency, and safety has driven automotive manufacturers to explore cutting-edge technologies and production methods. Among these, investment casting has emerged as a stalwart, quietly revolutionising the way critical components are crafted.

Within the sprawling landscape of automotive engineering, investment casting offers a refined approach to materialising intricate designs and achieving a delicate balance between strength and weight. This blog post embarks on a journey through the annals of automotive manufacturing, shedding light on the profound impact of investment casting and the innovations that have reshaped the sector.

Overview

Lightweighting in Automotive Design

The pursuit of lightweighting in automotive design has become increasingly paramount in an era where fuel efficiency and emission reduction are at the forefront of industry priorities. Investment casting plays a critical role in this endeavour, offering a pathway to produce lighter components without compromising on strength or performance.

Lightweight materials, such as aluminium and magnesium alloys, are central to reducing the overall weight of vehicles. The use of these materials allows for the creation of parts that are not only lighter but also inherently strong and durable. This is particularly significant in the development of components like engine blocks, transmission cases, and chassis elements, where weight plays a crucial role in the vehicle’s overall efficiency.

Investment casting contributes to lightweighting efforts by enabling the production of components with optimised designs. The flexibility of the casting process allows for the creation of shapes and structures that would be challenging, if not impossible, to achieve through traditional manufacturing methods. These optimised designs often result in parts that use less material, thereby reducing weight, while maintaining or even enhancing their functional integrity.

Moreover, investment casting facilitates the integration of multiple components into single, unified parts. This not only reduces the overall number of components in a vehicle but also minimises the need for fasteners and welds, further contributing to weight reduction. Such integrations are not only beneficial in terms of weight savings but also enhance the overall aesthetic and aerodynamic properties of the vehicle.

The impact of lightweight components on fuel efficiency cannot be overstated. Lighter vehicles require less energy to operate, leading to significant improvements in fuel economy. This, in turn, translates to lower CO2 emissions, aligning with global efforts to combat climate change. In addition, the enhanced performance and handling characteristics that result from reduced vehicle weight contribute to an improved driving experience.

Engine and Exhaust Components

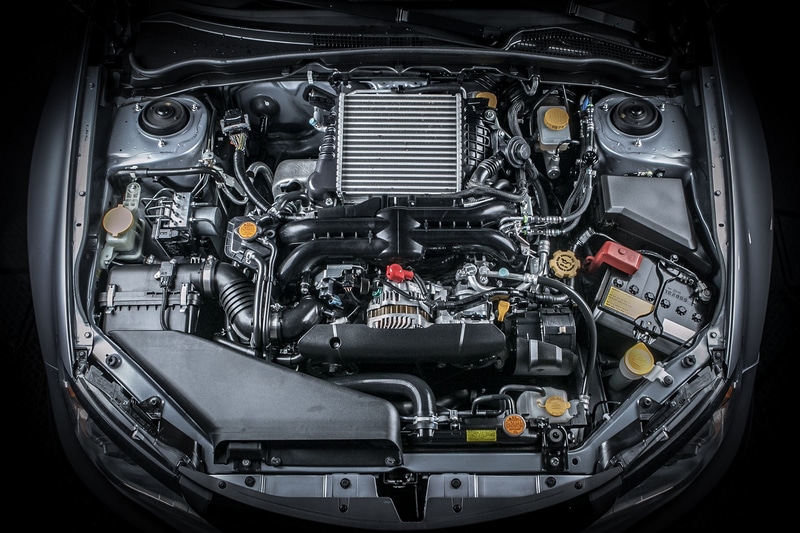

The manufacturing of engine and exhaust components represents one of the most demanding aspects of automotive design, requiring materials and processes that can withstand extreme temperatures and pressures. Investment casting emerges as a particularly apt solution in this context, adept at handling the complexities and stringent requirements of these critical parts.

Investment casting is favoured for engine and exhaust components due to its ability to produce parts with intricate geometries and exceptional dimensional accuracy. This precision is crucial for engine parts, where even minute deviations can significantly impact performance and efficiency. Components such as turbocharger wheels, exhaust manifolds, and cylinder heads are routinely produced using this method, benefitting from the fine surface finish and complex internal passageways that investment casting can achieve.

The high-temperature resistance of materials, such as nickel-based superalloys and stainless steel, is critical for exhaust system components. These materials can endure the intense heat and corrosive environments typical of exhaust applications, ensuring longevity and reliability. The process’s adaptability allows for the incorporation of design features that optimise airflow and reduce backpressure, enhancing engine efficiency and performance.

Furthermore, investment casting offers significant advantages in terms of design flexibility and integration. Complex and multi-functional components can be cast as single pieces, eliminating the need for assembly and reducing potential failure points. This integration is vital in modern engine design, where space constraints and weight reduction are paramount considerations.

Safety Components and Structural Parts

The importance of safety in the automotive industry cannot be overstated, with every component playing a crucial role in ensuring the well-being of passengers and the integrity of the vehicle. Investment casting has emerged as a key manufacturing process in the production of safety components and structural parts, offering a unique combination of strength, precision, and design flexibility.

Investment casting is particularly suited for producing complex, load-bearing components that are essential for vehicle safety. These include parts such as steering knuckles, suspension arms, and other structural elements that must withstand significant stress and strain during the vehicle’s lifespan. The process’s ability to work with a range of durable alloys ensures that these components are not only strong but also meet the stringent safety standards set by automotive regulatory bodies.

One of the standout features of investment casting in safety component manufacturing is its ability to produce parts with intricate internal structures. This capability is critical in creating components that are both lightweight and robust, contributing to overall vehicle safety without compromising on performance. The process also allows for the integration of multiple functions into single, cohesive units, reducing the need for additional assemblies and potential points of failure.

Investment casting plays a vital role in the manufacturing of bespoke safety components for high-performance and luxury vehicles, where customisation and exceptional quality are crucial. The flexibility in design and material choice offered by this process allows manufacturers to tailor components specifically to the unique requirements of these specialised vehicles.

Cost-Effectiveness of Investment Casting

In an industry where economic efficiency is as crucial as technical prowess, investment casting stands out not only for its manufacturing capabilities but also for its cost-effectiveness.

One of the primary advantages of investment casting in terms of cost-effectiveness is its ability to produce complex shapes and intricate details in a single step. This reduces the need for extensive machining and assembly, which can be both time-consuming and costly. By minimising these additional processes, investment casting significantly cuts down on production time and labour costs, offering a more streamlined and efficient manufacturing route.

The precision of investment casting leads to lower material wastage. The process allows for the production of near-net-shape parts, meaning the components require little to no finishing work. This efficiency not only reduces material costs but also minimizes the environmental impact by decreasing scrap.

Investment casting is also notable for its versatility in working with a wide range of materials. This flexibility allows manufacturers to choose the most cost-effective alloys for their specific requirements without compromising on quality or performance. Whether it’s standard steel, lightweight aluminium, or high-performance superalloys, investment casting can adapt to the economic and technical demands of various automotive applications.

In addition to its direct cost benefits, investment casting contributes to long-term savings. The durability and high-quality of cast components mean fewer replacements and less maintenance over the vehicle’s lifespan. This longevity is particularly important in the automotive sector, where the cost of recalls and repairs can be significant.

Advancements in Materials and Alloys

The continuous advancement in materials and alloys plays a transformative role in the automotive industry, particularly in the context of investment casting. This section examines how recent innovations in materials used for investment casting are enhancing the performance and durability of automotive components.

Investment casting has evolved significantly with the introduction of new materials and alloys, each offering unique properties that cater to the specific demands of automotive applications. These advancements have not only improved the quality and resilience of components but have also opened up new possibilities in automotive design and functionality.

One of the key developments is the use of advanced aluminium and magnesium alloys in investment casting. These materials are renowned for their strength-to-weight ratio, making them ideal for producing lightweight components that contribute to overall vehicle efficiency. Their use has become increasingly prevalent in the production of structural components, engine parts, and gears, where reducing weight without compromising strength is essential.

Another significant advancement is in the utilisation of high-temperature alloys, particularly in the manufacture of engine and exhaust components. These alloys, including nickel-based and cobalt-based superalloys, offer exceptional resistance to thermal and mechanical stress, ensuring durability in harsh operating conditions. Their application has been pivotal in enhancing the longevity and reliability of critical engine parts.

Furthermore, the development of more environmentally sustainable materials aligns with the industry’s growing commitment to eco-friendly manufacturing practices. These new alloys not only reduce the environmental footprint during production but also contribute to the recyclability of components at the end of their lifecycle.

Conclusion

As we conclude our exploration of the transformative impact of investment casting in the automotive industry, it becomes evident that this technique is not just a manufacturing process but a cornerstone of innovation and efficiency. Investment casting, with its precision, versatility, and adaptability, has proven to be an invaluable asset in addressing the industry’s challenges of lightweighting, safety, cost-effectiveness, and sustainability.

Taiyuan Simis Investment Casting Co., Ltd. stands as a beacon of excellence and innovation. With years of experience and a commitment to quality, Taiyuan Simis has established itself as a leader in the field. The foundry’s strength lies in its deep understanding of the investment casting process, combined with a relentless pursuit of technological advancement.

Equipped with advanced equipment and state-of-the-art facilities, Taiyuan Simis offers a range of services that cover the entire spectrum of investment casting needs. From the production of intricate engine components to the crafting of robust safety parts, their expertise is evident in the precision and quality of the components they produce. The company’s ability to work with a wide array of materials, including the latest alloys and sustainable materials, further enhances its capability to meet the diverse and evolving demands of the automotive industry.

we not only exemplifies the technical prowess required in modern investment casting but also embodies the principles of sustainable manufacturing. Their processes are designed to minimise waste, maximise efficiency, and reduce environmental impact, aligning with the global shift towards eco-friendly production practices.

As the automotive industry continues to evolve, facing new challenges and embracing innovative solutions, the role of investment casting will undoubtedly expand. Companies like Taiyuan Simis Investment Casting Co., Ltd. will be at the forefront, driving the industry forward with their experience, advanced technology, and unwavering commitment to quality and sustainability. The future of automotive manufacturing, shaped by investment casting, promises not only enhanced performance and efficiency but also a more sustainable pathway for the industry.