Language:

Why Automated Manufacturing is the Promising Future: 5 Compelling Reasons

Have you ever wondered what drives the relentless march of progress in manufacturing industry? In an era where efficiency and innovation are paramount, the answer increasingly lies in the realm of automated manufacturing. This technological marvel is transforming the industry, heralding a new age of production where precision, speed, and adaptability are at the forefront.

Automated manufacturing is not merely a fleeting trend; it is a revolutionary shift in how we approach the creation of goods. It stands as a beacon of progress, signifying the transition from traditional, labour-intensive methods to sophisticated, technology-driven processes. The significance of this transformation cannot be overstated, as it reshapes the very foundations of manufacturing, impacting everything from small-scale operations to global industrial giants.

In this article, we will delve into the five compelling reasons why automated manufacturing is unequivocally the future. From the stark improvements in efficiency and productivity to the unparalleled advancements in quality and innovation, automation is not just reshaping the present – it is defining the future. As we navigate through these reasons, it will become increasingly clear why embracing automated manufacturing is not just a wise choice for businesses, but an indispensable strategy for staying competitive and relevant in an ever-evolving industrial landscape.

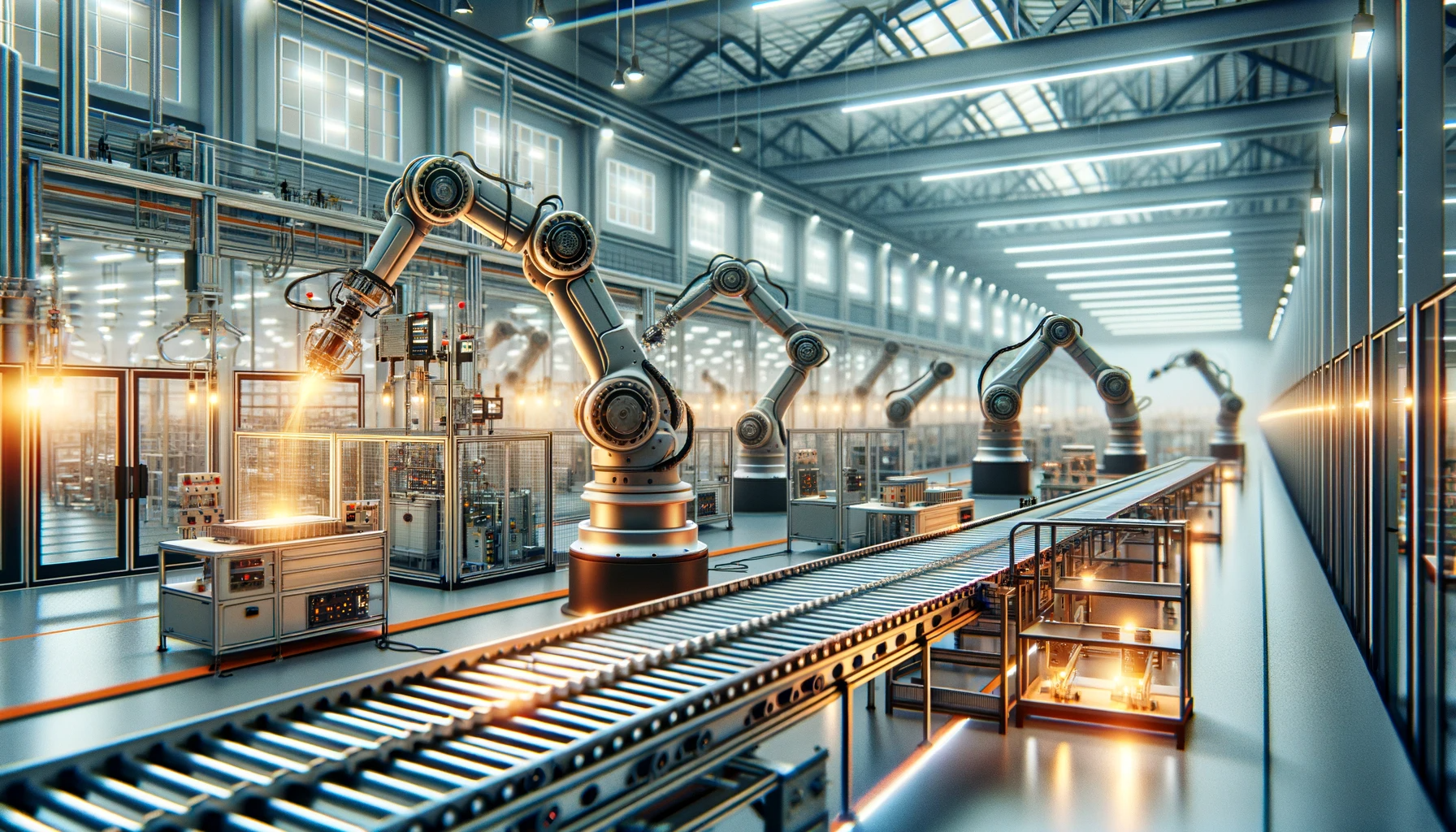

Automated Manufacturing Overview

1. Enhanced Efficiency and Productivity

One of the most transformative impacts of automated manufacturing lies in its remarkable enhancement of efficiency and productivity. Automation revolutionises the production process by integrating advanced technologies such as robotics, AI, and machine learning. These technologies enable manufacturing systems to operate with a level of speed and precision that is unattainable by human labour alone.

The efficiency of automated systems is evident in their ability to maintain consistent production rates around the clock. Unlike manual operations that are constrained by human work schedules and physical limitations, automated machines can function continuously without fatigue, leading to a substantial increase in output. This uninterrupted operation is crucial in meeting the high demand and tight deadlines that characterise today’s market landscape.

Moreover, automated manufacturing minimises the occurrence of errors that are often associated with manual processes. Automated systems are programmed for precision, ensuring that each product meets stringent quality standards. This reduction in errors not only enhances productivity but also reduces waste and the need for rework, further streamlining the production process.

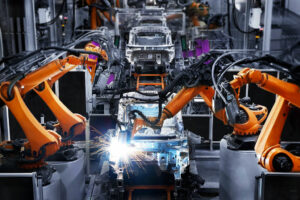

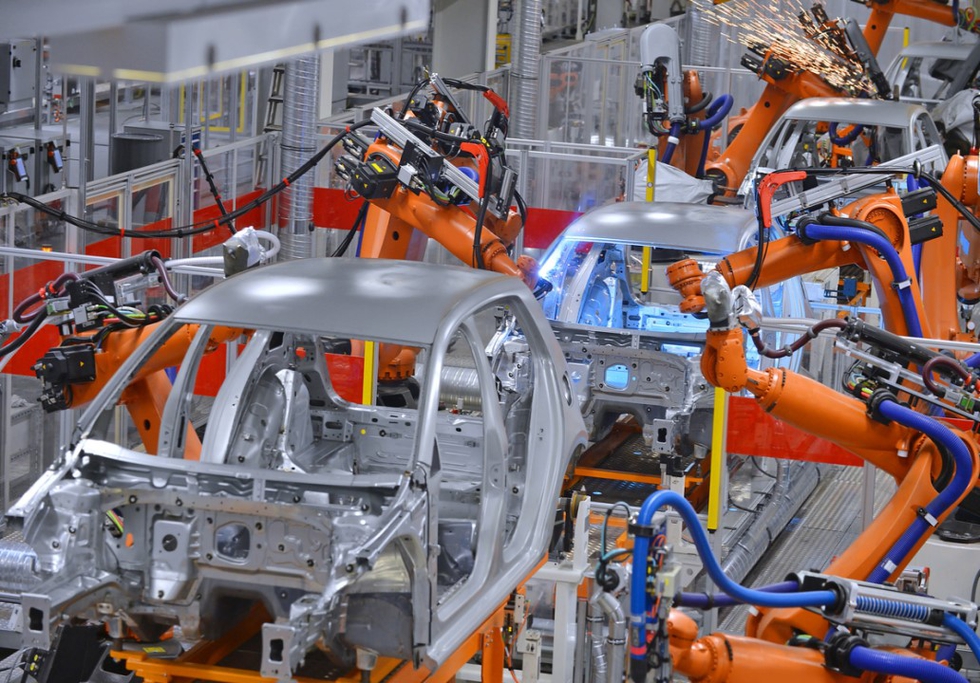

The adoption of automation has led to notable success stories across various industries. For instance, in the automotive sector, the implementation of robotic assembly lines has dramatically accelerated production rates while maintaining high-quality standards. Similarly, in the electronics industry, precision automation has enabled the mass production of intricate components with minimal error rates.

In essence, automated manufacturing sets a new benchmark for efficiency and productivity in the industrial world. It empowers businesses to meet the challenges of modern manufacturing demands, ensuring they remain competitive and capable of delivering products with both speed and quality.

2. Improved Quality and Consistency

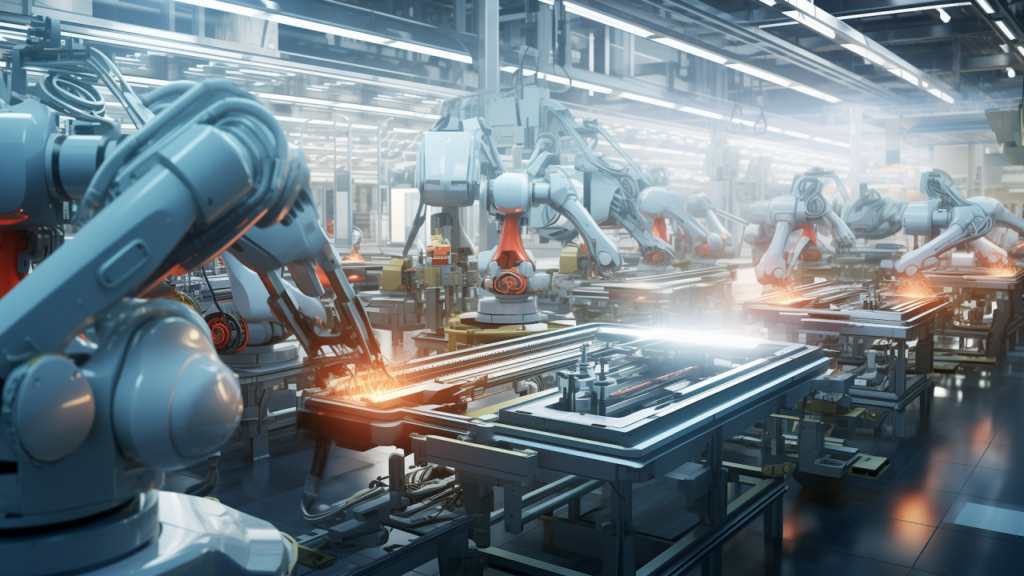

A cornerstone in the supremacy of automated manufacturing lies in its ability to consistently produce items of high quality. The precision and repeatability afforded by automation are unrivalled in traditional manufacturing setups. This consistency is crucial in industries where even minute deviations can lead to significant functional or safety issues.

Automated systems are designed to follow exact specifications and protocols, ensuring that every product meets the same high standard. Unlike manual production, where variability can creep in due to human error or fatigue, automated processes maintain uniformity in production. This level of consistency is especially vital in fields such as aerospace, medical devices, and pharmaceuticals, where the margin for error is negligible and the consequences of defects can be severe.

Furthermore, automation allows for real-time monitoring and quality control. Advanced sensors and diagnostic tools integrated into automated systems can detect and rectify defects immediately. This immediate feedback loop not only ensures the quality of each product but also enhances the overall efficiency of the manufacturing process by reducing wastage and the need for post-production quality checks.

The impact of automation on quality is evident in the precision engineering industries, where highly accurate components are paramount. For instance, in the semiconductor industry, the use of robotics and precision automation has been instrumental in achieving the levels of accuracy required for microchip production.

3. Cost Reduction and Profitability

A pivotal advantage of automated manufacturing is its significant impact on cost reduction and profitability. While the initial investment in automation technology can be substantial, the long-term financial benefits are undeniable. Automation streamlines the manufacturing process, reducing labour costs and enhancing productivity, which in turn leads to a higher return on investment.

The reduction in labour costs is one of the most immediate financial benefits of automation. Automated systems can perform the tasks of several workers and often more efficiently. This reduction in workforce requirements leads to significant savings on wages, training, and other employee-related expenses. Additionally, automation minimises the risks and costs associated with workplace injuries and related liabilities, which are more prevalent in manual operations.

Another area where automated manufacturing proves cost-effective is in its minimisation of material waste. Precision and consistency in production mean fewer errors and less material being discarded. For instance, in the automotive industry, the use of automated welding and painting systems has significantly reduced the amount of material wastage, contributing to both cost savings and environmental sustainability.

Automation contributes to profitability through increased production capacity. Automated machines can operate 24/7 without breaks, enabling manufacturers to produce more in less time. This increased capacity allows businesses to meet higher demand without the need for additional manual labour. For example, in the food and beverage industry, automation has enabled manufacturers to rapidly increase their output to meet seasonal demands without compromising on quality or efficiency.

4. Flexibility and Scalability in Production

Automated manufacturing is not only about efficiency and cost-saving; it’s also about the remarkable flexibility and scalability it offers. These attributes are increasingly important in today’s dynamic market, where consumer demands and technology trends are ever-evolving.

Automation offers unparalleled flexibility in production. With programmable and adaptable machinery, manufacturers can quickly switch between product lines or adjust production processes with minimal downtime. This adaptability is essential in industries where product life cycles are short or where there is a need for customisation. For instance, in the electronics industry, manufacturers can swiftly reconfigure automated assembly lines to accommodate different types of gadgets, adapting to the rapid pace of technological advancement and consumer preferences.

Scalability is another key advantage of automated systems. As business grows or market demands fluctuate, automated manufacturing lines can be scaled up or down without the extensive restructuring that manual processes would require. This scalability ensures that businesses can respond efficiently to market changes without incurring prohibitive costs. A case in point is the fashion industry, where automated textile manufacturing has enabled brands to scale production in line with seasonal trends and rapidly changing consumer tastes.

Moreover, the integration of digital technologies, such as the Internet of Things (IoT) and cloud computing, has further enhanced the flexibility and scalability of automated systems. These technologies allow for real-time monitoring and control of production processes, enabling manufacturers to optimise operations and respond swiftly to any production challenges.

5. Advancing Innovation and Competitiveness

The implementation of automated manufacturing is a driving force behind innovation in production techniques and product design, fostering a culture of continuous improvement and competitiveness in the global market. The integration of automation technologies is not merely a means to enhance efficiency; it’s a catalyst for transformative changes in the way products are conceived, designed, and brought to market.

Automation encourages innovation by enabling manufacturers to experiment with new processes and techniques that were previously impractical or impossible with manual methods. For instance, the use of robotics in automated manufacturing has led to the development of new fabrication methods in the aerospace industry, where precision and innovation are critical. Robotic arms can execute complex tasks with a level of precision and flexibility that far surpasses human capabilities, allowing for the creation of intricate and lightweight components.

Automation is intrinsically linked to the rise of Industry 4.0 – the ongoing automation of traditional manufacturing and industrial practices using modern smart technology. The integration of AI, machine learning, and data analytics in manufacturing processes leads to smarter, more efficient production lines that can predict maintenance needs, optimise operations, and adapt to new manufacturing challenges. This smart manufacturing approach is reshaping industries, as seen in the automotive sector, where predictive maintenance and real-time monitoring have significantly improved production efficiency and product quality.

In addition, automated manufacturing enhances competitiveness on a global scale. Companies that embrace automation can produce higher-quality products at a faster rate and lower cost, positioning them favourably in the international market. This competitive edge is crucial in today’s global economy, where manufacturers must continually innovate and adapt to remain relevant.

Our Advantages in Automated Manufacturing

As we have navigated through the transformative aspects of automated manufacturing, it becomes abundantly clear that this approach is not merely a component of modern industrial strategy, but a fundamental pillar of future manufacturing success. The advantages it offers in efficiency, quality, cost-effectiveness, flexibility, innovation, and global competitiveness are undeniable. These factors collectively underscore the essential role of automation in shaping the future of manufacturing.

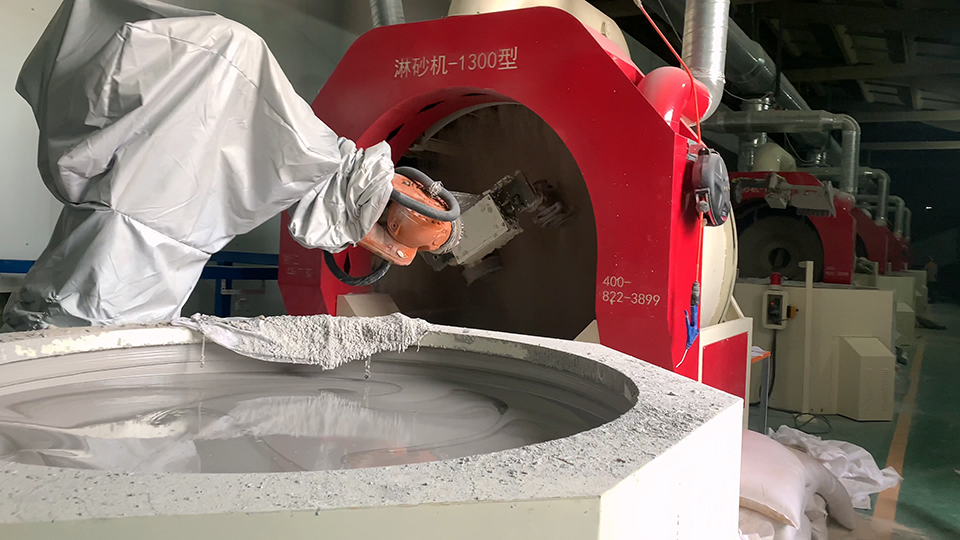

In the investment casting sector, Taiyuan Simis Investment Casting Co., Ltd. stands as a sterling example of how automated manufacturing can be harnessed to its fullest potential. Embracing the power of automation, Taiyuan Simis has equipped its facilities with advanced automated equipment, including automated wax injection machines, shell building robots, automated de-waxing equipment, robotic pouring systems, and automated cleaning and finishing equipment. These state-of-the-art technologies underscore the company’s commitment to innovation and excellence in investment casting.

By integrating these automated systems into their production processes, Taiyuan Simis Investment Casting Co., Ltd. has significantly enhanced its manufacturing efficiency and output quality. The precision afforded by automated wax injection machines ensures consistency in the creation of wax patterns, a critical step in investment casting. The utilisation of shell building robots and automated de-waxing equipment further streamlines the production process, maintaining high standards of quality while reducing manual labour requirements. The incorporation of robotic pouring systems guarantees precision in the most crucial phase of casting, ensuring the integrity and quality of the final product. Finally, the automated cleaning and finishing equipment ensures that each cast component meets the exacting standards expected by clients.

In conclusion, Taiyuan Simis Investment Casting Co., Ltd. exemplifies how automated manufacturing, particularly in the specialised field of investment casting, is not just a futuristic concept, but a present-day reality that is driving efficiency, quality, and innovation. Their approach to automation places them at the forefront of the industry, showcasing the immense potential of automated manufacturing processes. As the manufacturing world continues to evolve, companies like Taiyuan Simis are leading the way, demonstrating that the future of manufacturing is not only automated but also bright with possibilities.