Language:

Carbon Steel: The Most Popular Steel in Manufacturing, Here’s Why

Why does carbon steel hold such a distinguished position in the manufacturing industry? This blog seeks to answer this question, delving into the unique properties and widespread applications of this fundamental material. Carbon steel, an alloy primarily composed of iron and carbon, stands as a linchpin in a multitude of industrial processes, owing to its versatility and strength.

Ranging from low to high carbon variants, each type of carbon steel is adeptly tailored to meet specific needs and challenges across various sectors. From forming the backbone of architectural marvels to its crucial role in automotive engineering, the adaptability of carbon steel is unparalleled. It is this multifaceted nature that cements its status as not just a preferred material but a cornerstone in the field of manufacturing.

Our exploration will traverse the diverse aspects of carbon steel – its composition, intrinsic properties, and the integral part it plays in different manufacturing domains. We aim to uncover the core attributes that make carbon steel a ubiquitous and indispensable resource: its robustness, malleability, and economical value. Additionally, a comparative analysis with other materials will be undertaken to underscore its predominant role and versatility.

Table of Contents

What is Carbon Steel?

At the heart of the manufacturing industry’s reliance on carbon steel lies its fundamental nature and composition. What exactly is this material, and what makes it so versatile and indispensable? This section aims to demystify carbon steel, providing an understanding of its basic characteristics and the various types available.

Definition and Composition: Carbon steel, at its core, is an alloy primarily made up of iron and carbon. The amount of carbon in the alloy significantly influences its properties and classifies it into various categories. Carbon acts as a hardening agent, preventing iron atoms from dislocating and thus, enhancing the strength and durability of the steel.

Types of Carbon Steel: It can be broadly categorised into three types, each serving distinct applications and purposes.

- Low Carbon Steel: Often referred to as mild steel, contains approximately 0.05% to 0.25% carbon by weight. This type of steel is known for its ductility, weldability, and relatively low tensile strength. It is commonly used in construction and for manufacturing automotive parts.

- Medium Carbon Steel: Contains about 0.25% to 0.60% carbon, along with a combination of additional elements like manganese. Medium carbon steel offers a balance between durability, strength, and ductility. It is typically used in the production of gears, railway tracks, and machine parts.

- High Carbon Steel: With a carbon content ranging from 0.60% to 1.25%, it is exceptionally hard and strong, but less ductile. This type is frequently employed in high-strength wires, springs, and cutting tools.

Historical Context: The use of carbon steel dates back centuries, with its evolution closely tied to industrial advancements. Over time, the refinement in the production of carbon steel has enhanced its qualities, making it a material of choice for a vast array of applications.

Understanding the basic composition and types of carbon steel is crucial in comprehending its applications and the reasons behind its extensive use in manufacturing. The alloy’s inherent versatility, derived from its fundamental properties, sets the stage for its widespread applicability and dominance in the industrial sector.

Precision and Complexity

The remarkable precision and complexity achievable with carbon steel underscore its widespread application in manufacturing.

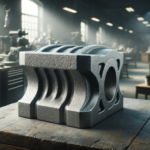

Detail and Accuracy: Carbon steel’s adaptability in terms of carbon content allows for the precise tailoring of its mechanical properties. This adaptability is pivotal in achieving the desired levels of detail and accuracy in manufactured parts. For example, high carbon steel, known for its hardness and strength, is ideal for cutting tools and wear-resistant parts where precision is crucial.

Complex Geometries and Intricate Designs: The versatility of carbon steel extends to its ability to be moulded into complex shapes and designs, especially in investment casting. Medium carbon steel, with its balance of strength, ductility, and hardness, is often used in structural components that require intricate shaping, such as automotive chassis or machinery parts. The steel’s workability ensures that even the most complex designs are achievable without compromising on strength or durability.

Superior Surface Finish: In addition to its structural capabilities, carbon steel can be finished to a high standard, making it suitable for applications where both functionality and aesthetics are important. Techniques such as polishing, plating, or coating can be applied to enhance corrosion resistance and appearance, further broadening its range of applications.

Advantages in Diverse Industries: The precision and complexity attainable with carbon steel make it a favoured material in industries such as automotive, where it is used to manufacture high-strength components like gears and shafts. In construction, its ability to support complex architectural designs while providing structural strength is invaluable. Similarly, in the production of precision instruments and machinery, its characteristics are crucial for the fabrication of intricate and reliable components.

In essence, the capacity of this alloy to be shaped into detailed, complex, and high-quality forms is a key factor in its popularity across various manufacturing domains. Its ability to meet precise specifications and accommodate complex designs underpins its reputation as a versatile and reliable material in the industrial world.

Material Versatility

The remarkable adaptability of carbon steel across a wide range of applications is a cornerstone of its popularity in the manufacturing sector. This section explores the material versatility of carbon steel, highlighting its suitability for various industries due to its diverse properties.

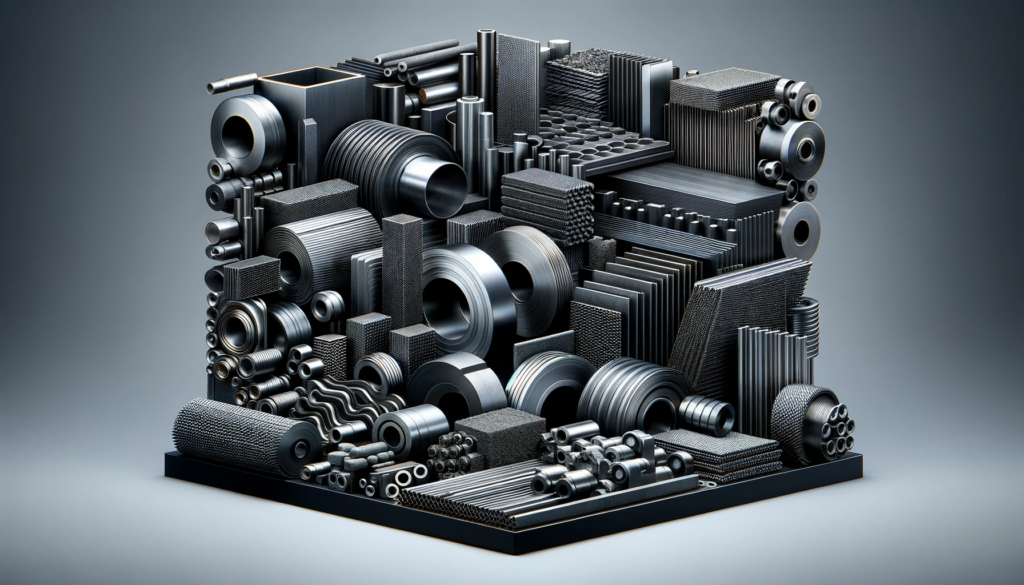

Range of Materials: Carbon steel’s versatility is largely attributed to the variable carbon content it possesses, which allows it to be modified to suit a wide array of mechanical and physical requirements. From low-carbon steels, known for their ductility and ease of forming, to high-carbon steels, prised for their strength and wear resistance, the range of materials within the alloy family addresses a broad spectrum of industrial needs.

Handling of High-Performance Alloys: Adding to its versatility, carbon steel can be alloyed with other elements like manganese, chromium, nickel, and vanadium to enhance certain properties. These alloyed steels, or high-strength low-alloy (HSLA) steels, combine the best attributes of carbon steel with the performance enhancements of other elements, making them ideal for demanding applications that require superior strength, toughness, and corrosion resistance.

Customisation: The ability to customise the composition of carbon steel is particularly advantageous. Depending on the alloying elements and heat treatment applied, carbon steel can be tailored to achieve specific properties such as increased hardness, improved formability, or enhanced corrosion resistance. This customisation capability enables manufacturers to produce steel that precisely fits the requirements of their application, whether it’s for robust construction materials, high-pressure pipelines, or delicate precision tools.

Environmental and Economic Benefits: Beyond its physical and mechanical versatility, carbon steel is also favoured for its environmental and economic benefits. It is one of the most recycled materials in the world, and its recyclability contributes to sustainable manufacturing practices. The efficiency in production and the abundance of iron ore also make carbon steel a cost-effective option for many applications.

The material versatility of carbon steel is a key attribute that underscores its widespread use in manufacturing. Its ability to be customised and modified to meet specific requirements makes it a highly adaptable and practical choice for a myriad of applications, from the construction of large-scale structures to the crafting of precision tools and components.

Cost-Effectiveness and Efficiency

The cost-effectiveness and efficiency of carbon steel in manufacturing processes solidify its status as a preferred material in various industries. This section focuses on how carbon steel delivers economic benefits while maintaining high standards of quality and performance.

Reduced Machining and Secondary Processing: One of the most significant advantages of carbon steel is its formability, particularly in the case of low-carbon steel. This malleability allows for easier shaping and machining, resulting in reduced processing time and lower costs. The ability to achieve the desired shape and specifications directly from the casting or forging process minimizes the need for extensive secondary machining, thus reducing overall production costs.

Economical for a Wide Range of Applications: Carbon steel’s cost-effectiveness is evident across its various grades. While high-carbon steel is ideal for producing durable and wear-resistant parts, it is still more economical compared to many other high-strength materials. Low and medium-carbon steels offer an excellent balance of strength, ductility, and cost, making them suitable for a wide range of budget-sensitive applications.

Tooling Longevity and Maintenance: The durability of carbon steel also extends to the longevity of the tools and machinery used in its processing. Carbon steel’s wear resistance contributes to less frequent tool changes and maintenance, which is an important consideration in reducing operational costs.

Waste Reduction and Material Savings: The efficiency of carbon steel in manufacturing also contributes to waste reduction. Its recyclability is a key factor in this regard, allowing scrap steel to be remelted and reused, which not only conserves raw materials but also reduces waste disposal costs. Moreover, the efficient use of such alloy in production processes means less material is wasted, contributing to overall material savings.

In conclusion, the cost-effectiveness and efficiency of carbon steel are rooted in its material properties, its adaptability in various applications, and its environmental sustainability. These factors collectively contribute to carbon steel’s status as a financially sensible and efficient choice in a multitude of manufacturing contexts, affirming its position as a staple material in the industry.

Design Flexibility and Innovation

In the domain of manufacturing, the ability to innovate and adapt designs is crucial for staying competitive. Carbon steel, with its inherent design flexibility, plays a pivotal role in facilitating innovation across various industries. This section explores how carbon steel enables designers and engineers to push the boundaries of creativity and functionality.

Design Freedom: Carbon steel’s versatile nature allows for an extensive range of design possibilities. Its ability to be forged or machined into complex shapes and sizes enables engineers to create bespoke solutions tailored to specific needs. This flexibility is especially beneficial in industries where customisation is key, such as bespoke machinery manufacturing or specialised automotive components.

Potential for Innovation: The malleability of low-carbon steel, combined with the strength and resilience of its higher carbon counterparts, provides a foundation for innovation. Engineers can exploit these properties to develop new, more efficient, and effective designs. For instance, in the automotive industry, the use of high-carbon steel in safety components offers both durability and impact resistance, essential for passenger protection.

Tailored Solutions: Carbon steel’s adaptability extends to its alloying potential, where elements such as manganese, chromium, and nickel can be added to enhance specific characteristics. This capability allows for the creation of tailored materials suited to unique operational environments, such as increased resistance to corrosion or improved heat tolerance.

Impact on Material Utilisation and Performance: Carbon steel’s flexibility in design also optimises material utilisation, reducing waste and enhancing overall performance. The ability to precisely align material properties with functional requirements ensures that each component performs optimally in its specific application, contributing to the longevity and reliability of the end product.

In essence, the design flexibility and potential for innovation are instrumental in driving progress across various manufacturing sectors. Its ability to meet diverse design requirements while maintaining high performance and reliability makes it an invaluable resource in the pursuit of engineering excellence and innovation.

General Applications

Carbon steel’s widespread popularity in manufacturing is not merely due to its material properties but also its extensive range of applications across various industries. This section outlines the general applications of carbon steel, demonstrating its versatility and indispensability in the industrial world.

Construction and Infrastructure: In the construction industry, carbon steel is fundamental for its strength and durability. It is used extensively in building frameworks, reinforcements, beams, and columns. The material’s ability to withstand heavy loads and environmental stresses makes it ideal for bridges, skyscrapers, and other large structures.

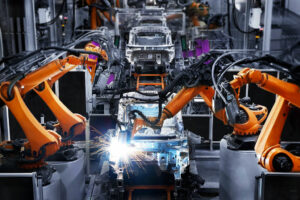

Automotive and Transportation: Carbon steel plays a critical role in the automotive sector. It is used in manufacturing body panels, frames, and other structural components of vehicles. In transportation, particularly in the railway sector, carbon steel is used for constructing rail tracks, components of the rolling stock, and in the heavy-duty frameworks of locomotives.

Machinery and Engineering: The versatility of carbon steel is evident in its use in machinery and heavy equipment. It is favoured for parts that require strength and resistance to wear and tear, such as gears, shafts, and hydraulic components. In engineering applications, carbon steel’s durability and workability make it suitable for creating a variety of tools and mechanical parts.

Consumer Goods and Appliances: Carbon steel finds its way into everyday life through consumer goods and appliances. Its use ranges from kitchen utensils and cutlery to larger household appliances. The material’s ability to be moulded into various shapes and its aesthetic appeal after finishing processes make it a popular choice in this sector.

Agricultural Equipment: In agriculture, carbon steel is used to manufacture a range of equipment, including tractors, ploughs, and irrigation systems. Its strength and resilience are crucial for equipment that must endure harsh working conditions and varying climates.

Medical Devices: The medical industry utilises it for various surgical and medical instruments. High-carbon steel, in particular, is used for its sharpness and durability in surgical blades and cutting tools.

Conclusion

From its inherent versatility and adaptability in various applications to its specific suitability for precision techniques like investment casting, carbon steel stands as a vital component in the world of manufacturing.

In this context, the role of companies like Taiyuan Simis Investment Casting Co., Ltd becomes particularly significant. As a China’s leader in the investment casting manufacturing, Simis has exemplified how the strategic use of alloy steel can lead to the creation of superior products. Their expertise in harnessing the qualities of carbon steel for investment casting has resulted in components that are not only precise and durable but also economically viable.

The versatility of carbon steel, as highlighted in various sectors such as construction, automotive, medical, and engineering, underscores its indispensability. Simis Casting’s proficiency in this field demonstrates the potential of carbon steel when combined with cutting-edge manufacturing techniques. Their commitment to quality and innovation stands as a testament to the capabilities of carbon steel in meeting the evolving demands of the modern industrial landscape.

In summary, carbon steel’s prominent role in manufacturing is undeniably a result of its unique properties and the advanced techniques employed in its processing. The contributions of companies like Taiyuan Simis Investment Casting Co., Ltd in this domain not only reinforce the value of the alloy but also drive the progression of manufacturing technologies. As we look towards the future, it is clear that carbon steel will continue to be a pivotal material, shaping the innovations and advancements in the industry.