Trending Now

Published 2 hours ago

SIMIS - A renowned Chinese foundry with 40 years of casting experience.

# Our strategic location in China’s major coal and steel production base ensures the availability and cost-effectiveness of raw materials, allowing us to offer competitive prices and customized solutions within budget.

Credentials Beyond Compare

We are a professional precision lost wax investment casting foundry that has obtained ISO 9001 certification. This signifies our commitment to quality management practices and our ability to consistently provide quality products and services that meet customer and regulatory requirements. In addition, we have been certified by TUV, demonstrating our adherence to high quality standards and our commitment to continuous improvement.

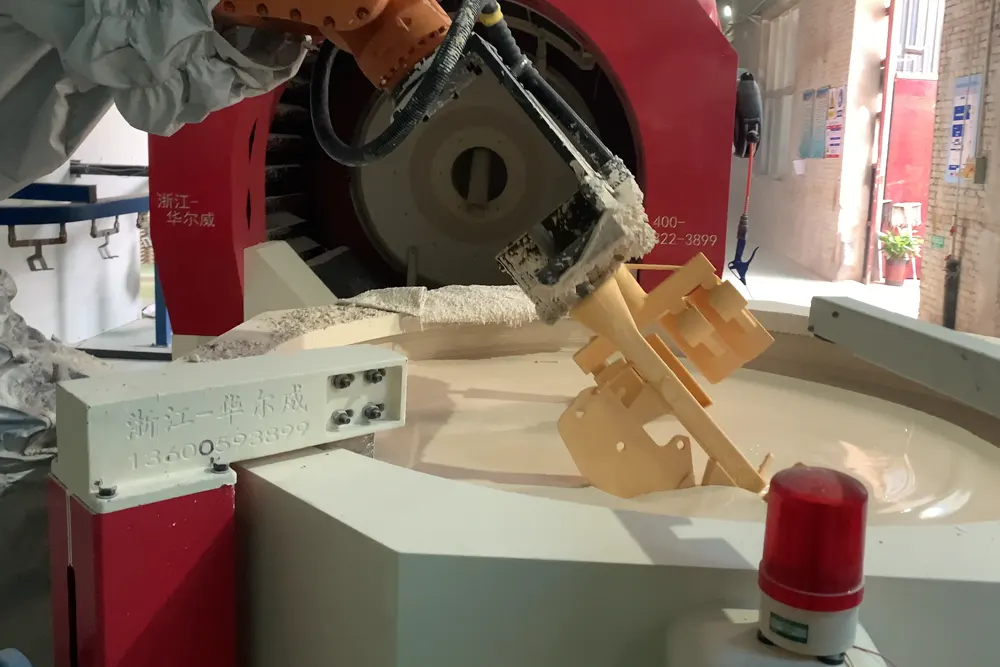

Our casting process:

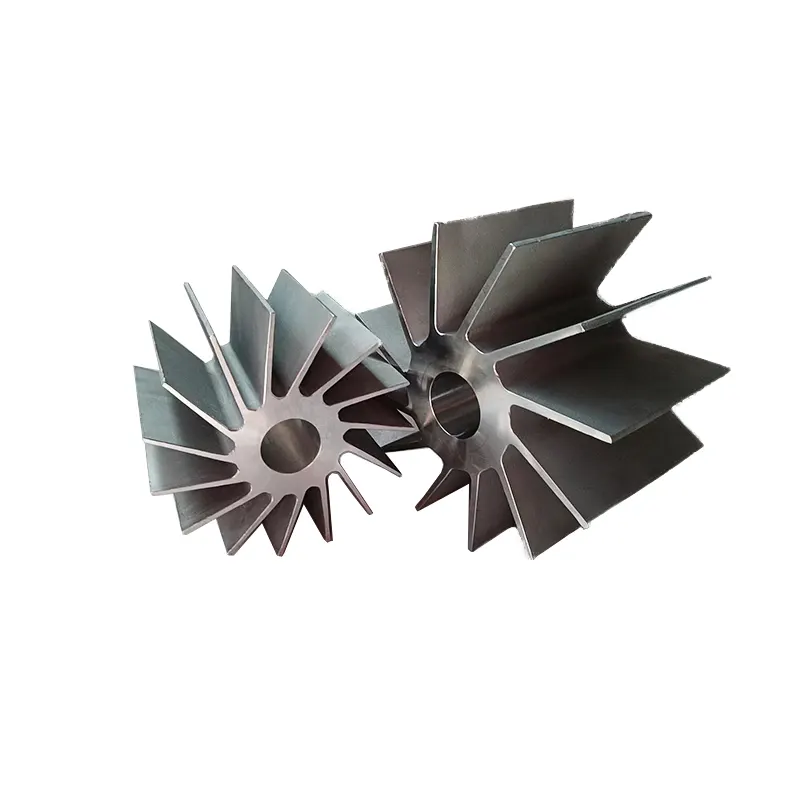

Investment casting (lost wax casting process) Product Gallery

If you are unable to obtain the required type of metal parts, it may affect your business growth and reputation. With 40 years of experience, we can manufacture custom metal parts using various metal materials, including carbon steel, high-alloy steel, stainless steel, aluminum alloy, ductile iron, and grey iron. We can provide high-quality metal parts according to your requirements to ensure that we meet your manufacturing needs.

Capable Of Solving The Toughest Casting Challenges.

Taiyuan SIMIS Investment Casting Company is a professional foundry that integrates development and production. We specialize in producing various kinds of investment casting parts and sand casting parts, which are widely used in industries such as automobiles, railway vehicles, medicine, aerospace, chemicals, machinery, construction, municipal works, pipelines, petrochemicals, mines, and electric utilities.

We are located in Taiyuan City, Shanxi Province, China. Shanxi Province has been known for its abundant reserves of iron ore, coal, and coke for a long time, which, combined with ample electricity supply, gives us a great advantage in producing ferrous metal casting parts, including cast iron parts and steel parts.

Why SIMIS?

Customization

Multiformity

Cost

Quality

Timeliness

Production Capacity

All-in-One Partner

Experience

Service

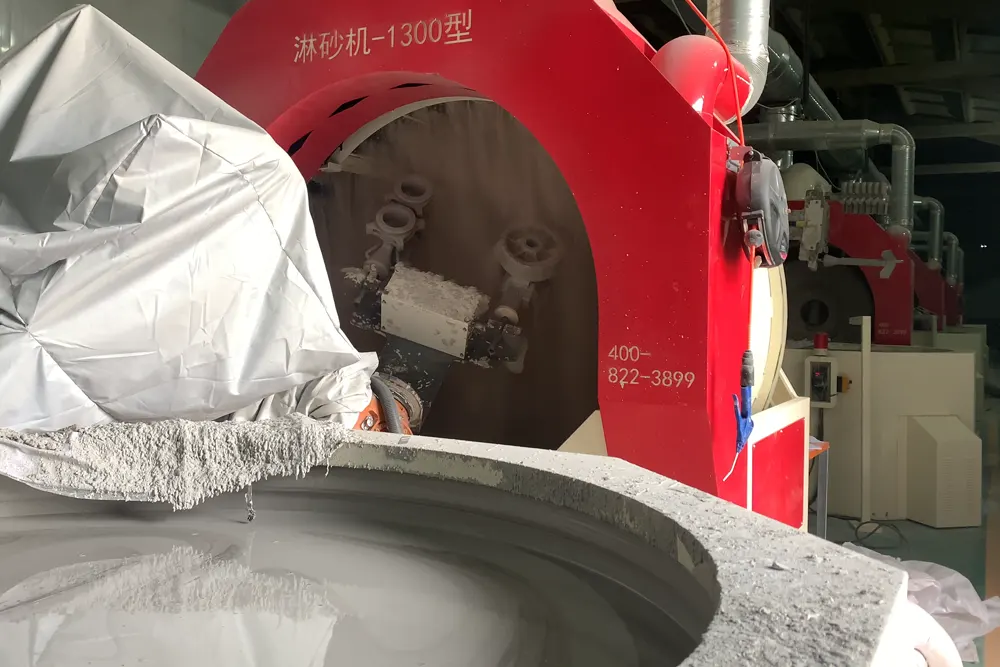

Advanced Production Facilities

We provide services to Fortune 500 companies, which demonstrates our ability to meet the high standards and expectations of some of the most successful and discerning businesses in the world.

Our foundry locate in the coal and steel energy product belt of China and provides us with a significant cost advantage.

TECHNICAL

We have comprehensive casting inspection methods. In 2008, we obtained ISO9000 quality management system and TS16949 quality certificates, which provide strong support for our quality assurance system. We have established a complete casting mechanical properties and chemical composition analysis testing center, which analyzes and tests the chemical composition and mechanical performance requirements for different materials. Key equipment includes:

1. Spectrometer

2. Mechanical performance tensile testing machine

3. Impact equipment capable of performing room temperature and low temperature (-45°C) impact tests, including machined impact test piece notch equipment

4. Metallographic inspection equipment

5. Rockwell hardness tester

6. X-ray detection equipment

7. Ultrasonic detector

8. Magnetic particle flaw detection equipment

9. Penetrant testing

You Asked, We Answered

Yes, we do not have a minimum quantity requirement. We produce as per the customer’s demand.

We have skilled smelters who can blend various metal materials to ensure the required chemical composition.

We have a laboratory that meets national requirements, with complete testing equipment and qualified personnel. During smelting, we perform three spectral analyses: the first during the furnace material melting stage, the second after alloy addition, and the third before steel production. If the composition does not meet the casting requirements, we adjust it promptly. Castings with qualified composition undergo heat treatment as per the requirements.

We have mold design, technical and inspection departments to maintain product safety. We have ISO9000 and TS16949 quality system certifications to ensure the safety of each production process. Over the years, we have not produced any defective products, so please rest assured to place orders.

We always believe that the customer is God and consider customer requirements as our top priority. We have an emergency department that specializes in emergency arrangements for urgent products to ensure timely delivery of every order.

Customize your ideal lost wax investment castings with us!

World Class Customer Base:Providing the Metalworking Industry with Castings, Fabrications, Forgings, Machining, and related products and services.