Language:

China's leading Investment Casting Manufacturer

With over 40 years of expertise, we are China’s leading investment casting manufacturer, specialising in the investment casting process, and a testament to our enduring commitment to excellence. Our journey, marked by a rich history of precision craftsmanship and innovation, has been defined by unwavering dedication. Our advanced equipment and an experienced engineering team work in harmony to craft custom metal parts that surpass expectations. Welcome to our world of precision casting, where experience meets innovation, and quality is our legacy.

Our Services

Taiyuan Simis specialises in investment casting, a process renowned for its ability to produce components with intricate details and exceptional precision. This method, also known as lost-wax casting, involves creating a wax pattern, which is then coated with a refractory ceramic material. Once the ceramic material hardens, the wax is melted away, leaving a detailed mould. Molten metal is poured into this mould, creating a casting that can achieve complex shapes and fine details. Our investment casting process is ideal for producing parts with a smooth finish and dimensional accuracy, suitable for a wide range of industries including aerospace, automotive, engineering machinery, locomotive, and medical devices.

The shell mould casting service at Taiyuan Simis involves creating a mould from a sand-resin mixture, which is then heated to harden. This technique allows for higher precision and better surface quality compared to traditional sand casting. Our shell mould casting process is adept at producing smaller, intricate parts with a high degree of accuracy and consistency. It is particularly beneficial for medium to high volume production runs, offering excellent dimensional stability and repeatability in components.

Sand casting is one of the most versatile casting processes we offer. It involves creating a mold from a sand mixture and pouring molten metal into the mold cavity. This process is suitable for a wide range of metals and alloys and is particularly effective for large components. Our sand casting service is known for its flexibility in terms of size and shape of components, and it is a cost-effective option for both small and large production runs. It’s an ideal choice for heavy equipment, industrial machinery, and automotive components.

Precision machining is a critical service we offer, encompassing a variety of techniques including milling, turning, drilling, and grinding. This process allows us to achieve tight tolerances and fine finishes on both cast and solid metal parts. Our state-of-the-art machining capabilities enable us to work with a wide range of materials and produce complex geometries with high precision. Precision machining is essential for finishing cast parts or for manufacturing components that require a high degree of accuracy, such as those used in the aerospace, medical, and electronics industries.

With our robust production capabilities and an experienced engineering team, we manufacture high-quality metal parts at a cost-effective price point. Whether your products are based on your designs or are general OEM products, we provide customised solutions tailored to meet your specific requirements.

Industries Served

We provide precision castings that serve a diverse range of mechanical sectors. With over 40 years of expertise as a seasoned investment casting manufacturer, we take pride in providing to clients in engineering machinery, agriculture machinery, building machinery, transportation, automobiles, trains, rail transit, the aerospace domain, and more. Our team of accomplished engineers and dedicated professionals ensures the production of top-tier castings customised to meet your precise requirements, establishing us as your trusted ally in the field.

Investment Casting Material

As a professional Chinese precision casting foundry, the materials used in our castings are versatile and can accommodate any type of casting material for your product, including high-strength steel, stainless steel, high-nickel steel, high-manganese steel, aluminum alloy, and more. Our commitment to precision and quality ensures that the castings we provide meet the highest industry standards, making us a reliable partner for your manufacturing needs.

Capable Of Solving The Toughest Casting Challenges.

Founded in the year 2004, Taiyuan SIMIS Investment Casting Company is a well-established foundry that seamlessly combines development and production. Our expertise lies in the creation of diverse investment casting parts and sand casting components, catering to a wide range of industries including automotive, railway vehicles, medical, aerospace, chemical, machinery, construction, municipal works, pipeline, petrochemical, mining, and the electric utility sector.

Taiyuan SIMIS Investment Casting Co., Ltd., boasts six affiliated casting facilities and two dedicated CNC machining workshops. Our location in Taiyuan City, Shanxi Province, China, provides us with a strategic advantage. Shanxi Province is renowned for its rich reserves of iron ore, coal, and coke. Coupled with a robust electricity supply, we have a distinct edge in producing ferrous metal casting components, including cast iron and steel parts.

Furthermore, we take pride in our ISO9001 certification, a testament to our commitment to maintaining the highest quality standards in all aspects of our operations.

Why Choose SIMIS?

Customisation

We have a robust R&D team capable of developing and producing products based on customer drawings or samples.

Multiformity

We have a variety of precision casting processes, including investment casting, shell casting, and sand casting, that enable us to meet diverse customer needs.

Cost Advantage

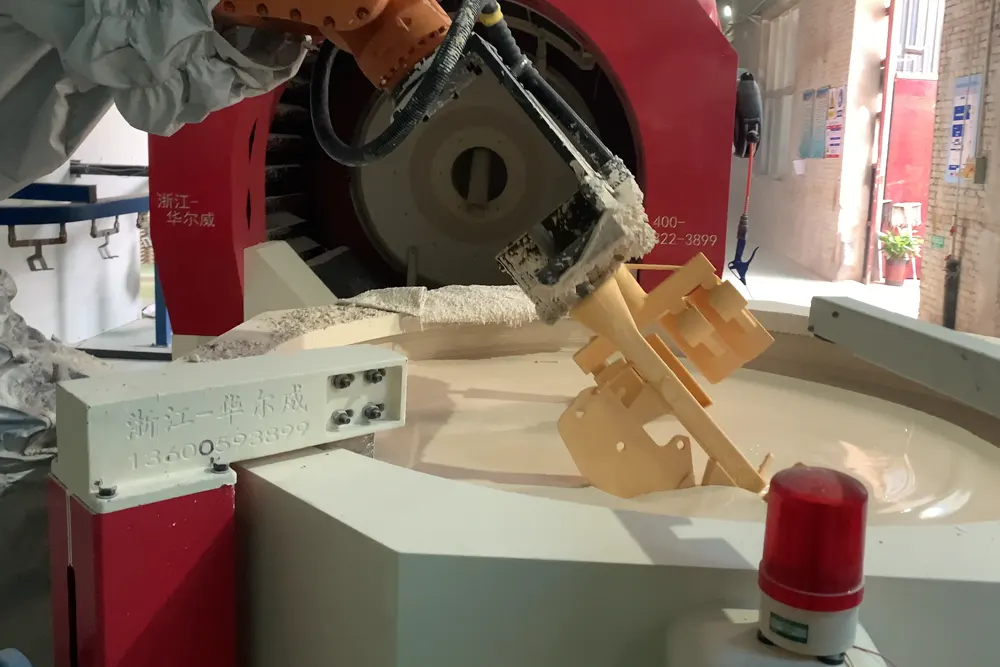

Thanks to the integration of numerous advanced robotic systems, the entire production chain has undergone substantial enhancements, resulting in cost savings and ensuring competitive pricing.

Quality Control

Our ISO-certified quality certification signifies that we maintain a rigorous quality control team, ensuring the consistent delivery of high-quality casting products. Our primary objective is to guarantee the quality of each product and minimise rejection rates to zero.

Timeliness

We are well aware of the repercussions of delayed orders, which can result in financial losses for our customers and impact the viability of our business. Our effective management ensures that such occurrences are prevented.

Production Capacity

Our strategic location within China’s coal and steel energy product hub affords us a notable cost advantage, benefitting from abundant and affordable electricity supply and favorable labor costs. Annually, we manufacture in excess of 5000 tons of investment castings, as well as a quantity of sand castings.

All-in-One Partner

We provide more than just manufacturing. We will support you throughout your project, from the time you imagine it to when it is completed, with the utmost precision and success. Our customers are located all over the world, including North America, Europe, Russia, and South Asia.

Experience

For over four decades, we have been trusted suppliers to world-class customers, a source of immense pride. Presently, our global reach encompasses a 90% export ratio, serving customers across the globe.

Service

Manufacturing isn’t solely about production; it’s equally about crafting an exceptional customer experience to ensure that your requirements are acknowledged and your specifications are fulfilled.

Advanced Production Facilities

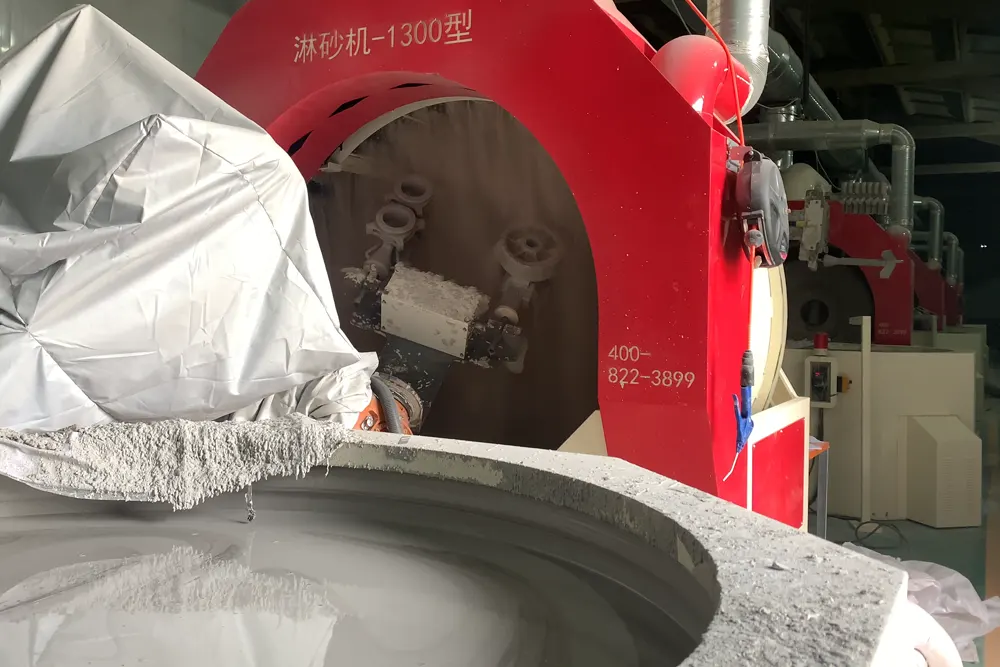

In the realm of investment casting in China, we proudly lead the way. Our commitment to excellence is evident in our continuous efforts to replace outdated, environmentally harmful casting materials and processes with modern solutions. Significant investments have been made in cutting-edge equipment, some of which are typically exclusive to the domestic automotive sector. These advancements in casting techniques and the adoption of advanced machinery have not only elevated the quality of our castings but have also significantly reduced our environmental impact.

Our equipment includes precision wax injection systems, advanced ceramic shell-making facilities, and top-notch induction furnaces. These investments have resulted in a substantial boost to our annual production capacity, now reaching an impressive 5000 tons.

Alongside our investment casting services, we extend alternative offerings in the form of sand casting, die casting, and shell casting. Our well-equipped facilities for these processes encompass high-capacity sand molding machines, advanced die casting equipment, and precision shell-making machinery.

Moreover, our commitment to comprehensive solutions extends to machining services. Our modern machining centres are equipped with CNC (Computer Numerical Control) machines, lathes, and milling apparatus, ensuring our capability to meet your specific machining requirements with the same level of precision and quality that characterises our casting services.

Our ongoing investments in cutting-edge technology and innovative processes reaffirm our standing as a professional investment casting foundry, steadfast in our holistic approach to serving our valued clients.

Credentials Beyond Compare

We are a professional investment casting foundry with a long-standing ISO 9001 certification, which reflects our ongoing dedication to maintaining high-quality management practices and our consistent delivery of top-notch products and services while meeting customer regulatory requirements. Additionally, we have received certification from TUV, affirming our commitment to upholding stringent quality standards and our continued pursuit of excellence.

Our Prominent Clients

Providing the Metalworking Industry with Castings, Fabrications, Machining, and related products and services.

Investment Castings

Our investment casting process is carried out by a professional and experienced team that is 100% dedicated to producing high-quality products. We excel at overcoming challenges posed by difficult and complex structures, special materials, and small order quantities. We can be your reliable partner.

Investment Castings

Investment casting, also known as lost wax casting, utilises high-quality alloys to produce a wide range of part sizes with exceptional accuracy. With a team that is fully dedicated to producing precision castings of the highest quality, we can deliver reliable investment casting parts that offer outstanding benefits for any application.

Request a Quote

Subscribe to the SIMIS Blog

Stay up to date with the latest in manufacturing and supply-chain management.

Trending now